Introduction

Fire safety is a critical concern in modern infrastructure, and it is particularly essential in environments where the risk of fire is elevated, such as in power plants, high-rise buildings, tunnels, and industrial facilities. One of the key components in ensuring the safety and functionality of electrical systems during a fire is the use of fire resistant cables. These cables are designed to maintain circuit integrity during fire conditions, allowing essential systems to continue functioning, such as emergency lighting, alarms, and communication systems.

They have become indispensable in enhancing fire safety, reducing the risk of electrical failure during fire, and providing crucial operational time for evacuation or firefighting efforts. This article delves into the nature of fire resistant cables, their working principles, types, applications, and essential characteristics that make them a preferred choice in high-risk environments.

What is Fire Resistant Cable?

Fire resistant cable, also known as circuit integrity cable, is a type of cable specifically designed to withstand high temperatures and maintain electrical function during a fire. Unlike standard cables, which fail quickly in extreme heat, they are built to resist burning and continue functioning for a specific period under fire conditions. These cables do not propagate flames, release toxic gases, or suffer significant insulation breakdown when exposed to fire.

They are often used in circuits critical to safety, such as fire alarm systems, emergency lighting, smoke detectors, and power supplies for firefighting equipment. They are a crucial element in ensuring the ongoing operation of essential systems that provide the time needed to respond effectively to an emergency, whether by evacuating occupants or extinguishing the fire.

How Fire Resistant Cables Work

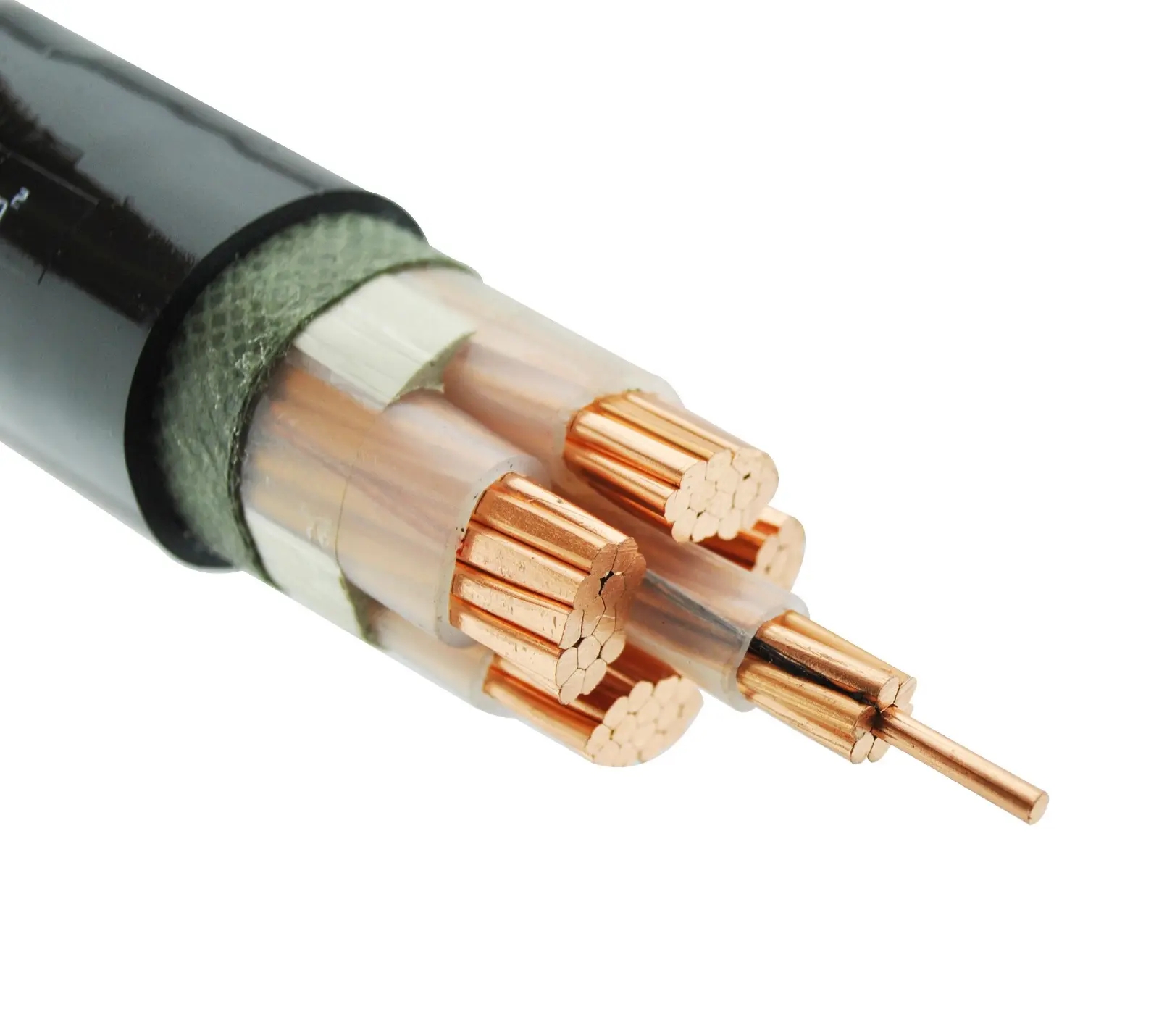

The principle behind fire resistant cables lies in their construction and material composition. These cables typically consist of a conductor (usually copper or aluminum) surrounded by layers of insulation materials specifically chosen for their heat-resistant properties. In such cables, the insulation materials are designed to retain their mechanical and electrical functions even when subjected to extreme heat.

Some of these cables include an additional layer of mica tape, which offers excellent thermal stability. Mica, a mineral known for its resistance to high temperatures, acts as an insulating barrier to prevent the conductor from short-circuiting or deteriorating during a fire.

The fire resistant properties of these cables are also dependent on the specific standards they are designed to meet. For example, certain fire resistant cables can maintain their integrity for up to two or three hours at temperatures exceeding 750°C (1382°F), depending on the standard they adhere to. These standards may vary based on the application, such as those required for oil and gas installations, railways, or buildings.

Characteristics of fire resistant Cables

- Heat Resistance: A key feature of fire resistant cables is their ability to endure high temperatures without losing functionality. These cables are designed to maintain circuit integrity when exposed to fire, making them suitable for safety-critical systems that must remain operational during emergencies. The capacity to resist temperatures typically ranges from 650°C to over 950°C, depending on the type and insulation materials used.

- Low Smoke and Halogen-Free Emissions: These cables are often designed with low-smoke, zero-halogen (LSZH) properties. In case of a fire, cables with halogen-free insulation do not release toxic or corrosive gases, enhancing safety for both people and equipment. LSZH cables are crucial in confined environments such as tunnels, aircraft, and ships, where smoke inhalation or corrosive gas exposure could pose serious risks.

- Flame Retardancy: In addition to their ability to withstand fire, fire resistant cables are engineered to limit the spread of flames. This is an important characteristic, preventing fire from traveling along the cable pathway and potentially moving between different sections of a building or facility.

- Circuit Integrity: Circuit integrity refers to a cable’s ability to maintain electrical continuity during and after fire exposure. This is critical to ensuring that emergency systems, such as alarms, lighting, and evacuation systems, continue to function in a fire situation. These cables undergo rigorous testing to ensure they can maintain electrical performance for a specified period under direct flame exposure.

- Durability and Mechanical Strength: They are designed not only to withstand fire but also to resist physical damage, such as impacts, abrasions, and bending. This durability ensures that they remain operational even in the harsh conditions typically associated with fire scenarios.

- Moisture and Chemical Resistance: In specific applications, cables may also require resistance to moisture and chemicals. This is especially important in industrial settings or outdoor installations, where exposure to water, oil, or other chemicals could affect performance. Certain fire resistant cables are designed with additional protective layers to ensure longevity in these challenging environments.

- Compliance with Fire Safety Standards: These cables are tested against international standards that define their performance under fire conditions. Standards such as BS 6387, IEC 60331, and EN 50200 set out the requirements for fire resistance and circuit integrity in various environments. Meeting these standards ensures the cables are up to the necessary safety and performance benchmarks for their intended use.

Types of fire resistant Cables

- Mineral Insulated Cables (MI) Mineral insulated cables are highly fire resistant and can withstand extreme temperatures for extended periods. They consist of a metal sheath (typically copper) filled with magnesium oxide powder, which acts as insulation. These cables are often used in environments with high fire risks, such as power plants, industrial plants, and oil and gas facilities.

- Silicon-Insulated Cables Silicon-insulated cables are another common type of it. Silicon is known for its high heat resistance and flexibility. These cables are often used in applications requiring fire resistance and mechanical flexibility, such as in elevators, emergency lighting circuits, and fire alarms.

- Mica Tape-Wrapped Cables Mica tape-wrapped cables use mica tape as the primary insulation material due to its excellent thermal stability. Mica is a non-flammable material that remains stable at very high temperatures, making these cables ideal for fire resistant applications. These cables are often used in situations where prolonged exposure to fire is anticipated.

Applications of fire resistant Cables

- Building Infrastructure: In buildings, they are used in systems that must remain operational during a fire, including emergency lighting, fire alarm systems, sprinkler systems, and communication systems. These cables provide critical time for safe evacuation and allow effective coordination of firefighting efforts.

- Transportation Infrastructure: In railways, subways, and tunnels, fire resistant cables ensure the continued operation of essential systems like signaling, lighting, and communication. Given the enclosed nature of these environments, minimizing smoke and toxic gas release is crucial for safety, making LSZH fire resistant cables a popular choice.

- Industrial and Power Plants: In industrial facilities, especially those involving flammable materials or high-energy processes, they are used to maintain the operation of vital control and power systems during a fire. Power plants, chemical plants, and oil refineries often employ these cables to ensure that safety systems, such as fire suppression and emergency shutdown mechanisms, remain functional during fire incidents.

- Marine and Offshore Applications: They are also widely used in ships and offshore platforms, where fire risks are elevated, and evacuation may be challenging. These cables are designed to function in harsh environments, including exposure to moisture, chemicals, and extreme temperatures.

Conclusion

Fire resistant cables play a vital role in enhancing the safety of buildings, industrial facilities, and transportation systems by ensuring the continuity of critical systems during fire events. Their ability to withstand high temperatures, prevent flame propagation, and emit minimal toxic gases makes them indispensable in modern safety infrastructure. From their construction and material composition to their varied applications, they are engineered to meet the highest safety standards, ensuring that electrical systems remain operational when they are needed most.