introduce

In the ever-evolving world of technology and communication systems, ANYTE cables play a vital role in ensuring the smooth transmission of data, power and signals. Among the various types of cables used, AWM (Appliance Wiring Material) cables stand out for their versatility and wide range of applications. This article aims to provide a comprehensive guide for AWM cable products such as awm ul2517, awm ul20234, awm single core cable, and discuss their definition, structure, application, advantages and future trends in the industry.

Learn about AWM cables

Definition of AWM Cable

AWM stands for Appliance Wiring Material. It is a cable that meets specific safety and performance standards, such as: awm ul2517, awm ul20234, awm single core cable, etc. It is suitable for a variety of applications, including household appliances, electronics, automotive and industrial machinery. AWM cables are designed to provide reliable electrical connections, withstand various environmental conditions and ensure safety in different settings.

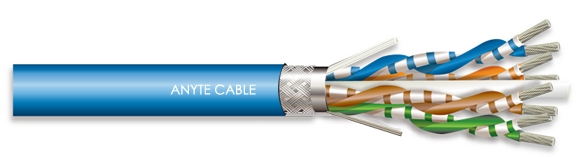

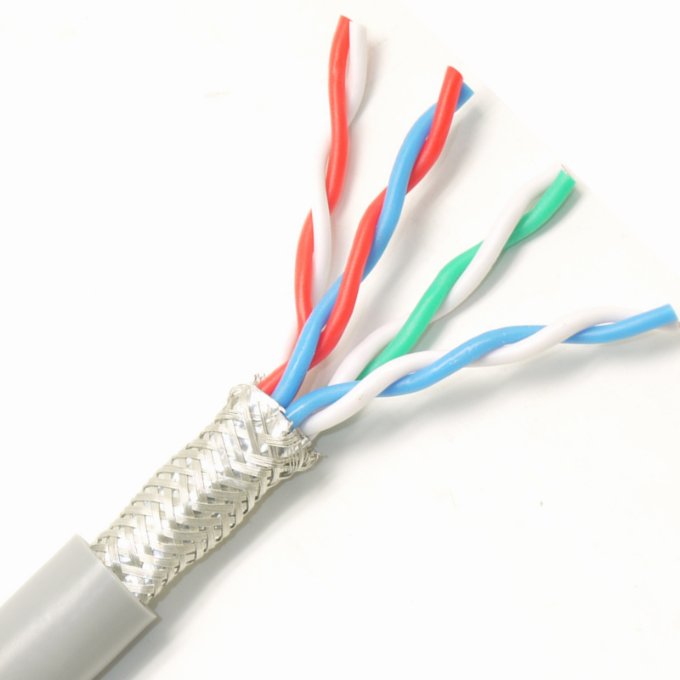

Structure and Components

AWM cables typically consist of several key components. Conductors, usually made of copper or aluminum, act as paths for the electrical current. Insulating material surrounds the conductors, providing electrical isolation and protection. The jacket is the outer shell of the cable that protects the internal components from mechanical damage, moisture and other external elements.

Different types and variants of AWM cables exist to meet different requirements. Some may be optimized for flexibility, while others prioritize resistance to high temperatures or specific environmental conditions.

Application of AWM cable

Electronics and Appliances

AWM cables’ awm ul2517, awm ul20234, awm single core cable and other products are widely used in consumer electronics such as TVs, computers and smart phones. Cables within these devices connect various components and ensure seamless data and power transfer. In addition, the internal wiring of household appliances such as refrigerators, microwave ovens and washing machines also rely on AWM cables.

Automobile industry

In the automotive industry, AWM cables are essential in building wire harnesses that connect the vehicle’s electrical systems. Cables used in automobiles must be able to withstand vibration, extreme temperatures and potential chemical exposure, making AWM cables an ideal choice.

Industry and Manufacturing

The industrial sector benefits greatly from AWM cables as they provide reliable connections for machinery and automation systems. Their high flexibility and resistance to mechanical stress make them suitable for use in factory automation and robotics.

Telecom and Datacom

AWM cables are critical to building high-speed internet and telecommunications infrastructure. They are commonly used in data centers, local area networks (LANs) and wide area networks (WANs). The cable maintains signal integrity over long distances, ensuring efficient data transmission.

Key Features and Benefits of AWM Cables

High flexibility and bendability

One of the significant advantages of AWM cable products such as awm ul2517, awm ul20234, awm single core cable is its flexibility. This feature allows them to be easily routed and installed in tight spaces or complex configurations, reducing installation challenges and potential cable damage.

Temperature Resistance and Operating Range

AWM cables are designed to withstand a wide range of temperatures, making them suitable for extreme hot and cold environments. This feature ensures consistent performance even under challenging conditions.

Fire and Safety Precautions

When it comes to electrical systems, safety is a top priority. AWM cables are usually designed with fire-resistant materials to prevent the spread of fire in the event of an accident or failure.

Electrical Performance and Signal Integrity

Maintaining signal integrity is critical to data communications. AWM cables are engineered to minimize signal loss and interference, ensuring efficient and reliable data transmission.

Durability and service life in various environments

AWM cables are able to withstand environmental elements such as moisture, chemicals and UV rays. Its durable construction ensures long life and reliable operation, even under harsh conditions.

Comparison with other cable types

AWM cable and THHN/THWN cable

Although both AWM and THHN/THWN cables are used in electrical applications, they have distinct differences. AWM cables’ products awm ul2517, awm ul20234, awm single core cable, etc. are designed to meet stricter safety standards and are usually used in electrical and electronic products. On the other hand, THHN/THWN cables are mainly used in building wiring applications.

AWM Cable vs. Coaxial Cable

Coaxial cables are often used for high-frequency signal transmission, such as cable television and Internet connections. In contrast, AWM cables are more versatile, with applications ranging from low-voltage electrical connections to high-speed data transmission.

AWM cables vs Ethernet cables

Ethernet cables are often called Cat5e, Cat6 or Cat7 cables and are designed for computer networking. AWM cables, while capable of handling data transfers, are not optimized for the same level of network performance as Ethernet cables.

Installation and Operating Precautions

Proper handling and storage of AWM cables

Prior to installation, AWM cables must be handled with care to prevent damage to their components. Proper storage in a clean, dry and climate-controlled environment is critical to maintaining its performance.

Installation and Wiring Guidelines

During installation, follow manufacturer guidelines and safety codes to ensure proper routing and support of AWM cables. Avoid sharp bends and bends that could cause signal attenuation or cable failure.

Comply with safety norms and regulations

Always follow local and national safety codes and regulations when installing AWM cables. Compliance ensures the safety of electrical systems and the people who interact with them.

Troubleshooting and Maintenance

FAQs and Problems with AWM Cables

Some common problems with AWM cables include signal loss, electrical shorts, and insulation breakdown. Understanding these issues can help in effectively diagnosing and resolving cable-related problems.

Troubleshooting Techniques for Cable Faults

Proper troubleshooting is critical to determining the root cause of cable failures. Techniques such as continuity testing and insulation resistance measurements can help diagnose cable problems.

General maintenance practices to ensure cable life

Regular inspections, regular maintenance and preventive measures can significantly extend the life of AWM cables. Cleaning and checking for signs of wear can prevent potential problems from escalating.

Future Trends and Innovations

Advances in AWM Cable Technology

The cable industry is constantly evolving, and AWM cables are no exception. Advances in materials, insulation, and manufacturing processes may lead to better performing and more efficient AWM cables.

Emerging Applications and Industries

As the technology expands into new areas, AWM Cable’s products awm ul2517, awm ul20234, awm single core cable, etc. will find applications in emerging industries such as renewable energy, smart grid, and Internet of Things (IoT) devices. Their versatility and adaptability make them ideal for integration into these cutting-edge technologies.

potential challenges and opportunities

Increasing demands for higher data speeds, energy efficiency and safety standards present challenges and opportunities for AWM cable manufacturers. Innovations in cable design and materials are critical to meeting the changing needs of various industries.

in conclusion

ANYTE as a cable manufacturer, AWM cable products awm ul2517, awm ul20234, awm single core cable, etc. have been proved to be an indispensable part of modern technology and communication systems. Its reliability, durability and safety features make it the first choice for a variety of applications, from household appliances to industrial machinery. As technology advances and new industries emerge, AWM cables will continue to evolve, ensuring seamless data and power transfer in the ever-changing modern connectivity environment.

ANYTE Cable Co., Ltd. is a leading cable manufacturer dedicated to providing high quality, advanced cable solutions. Establish partnerships with German cable manufacturers, and adopt German advanced manufacturing technology and design concepts in products. Consultation is available at any time if necessary.

Related Products