Introduction:

In the complex realm of electrical wiring, H07Z-K cables stand out with unique characteristics and diverse applications. This article delves into their intricacies, exploring key features, composition, applications, and compliance standards. A comprehensive understanding of these aspects is crucial for professionals in the electrical and construction industries, guiding them in making informed cable selection decisions.

I. Definition and Composition:

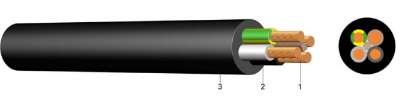

H07Z-K cables, part of the harmonized cable series, feature halogen-free properties and use thermosetting insulation. The “H” signifies the absence of halogens, while the “Z” indicates the thermosetting insulation. The “K” denotes fine-wire stranding, providing flexibility in installations. These cables typically consist of copper conductors and utilize a halogen-free, flame-retardant insulation material, making them suitable for various applications.

II. Key Characteristics:

- Halogen-Free Properties:

H07Z-K cables are characterized by their halogen-free composition, which means they do not contain chlorine, fluorine, bromine, or iodine. In the event of a fire, these cables emit minimal smoke and non-toxic gases, contributing to enhanced safety in enclosed spaces.

- Flame Retardance:

The flame-retardant nature of it ensures that it resists the propagation of fire. This feature is crucial in applications where fire safety is a primary concern, such as in residential, commercial, and industrial buildings.

- Thermosetting Insulation:

The “Z” designation indicates thermosetting insulation, which, unlike thermoplastic insulation, maintains stability under heat. This property prevents deformation and melting at high temperatures, ensuring reliable performance in various environments

- Fine-Wire Stranding (Class 5):

H07Z-K cables are often classified as Class 5 in terms of conductor stranding. This classification signifies fine-wire stranding, providing flexibility and ease of installation. The fine-wire construction allows for bending and routing in confined spaces without compromising the cable’s integrity.

- Wide Temperature Range:

These cables are designed to operate effectively across a wide temperature range. This adaptability makes them suitable for use in diverse climates and environments, from cold storage facilities to outdoor installations.

- Resistance to UV Radiation:

Some variants of H07Z-K cables are formulated with UV-resistant properties. This makes them suitable for outdoor applications where exposure to sunlight is unavoidable, ensuring that the cables maintain their performance and integrity over time.

- Chemical Resistance:

The halogen-free composition contributes to the cables’ resistance to various chemicals. This characteristic is particularly valuable in industrial settings where exposure to corrosive substances is prevalent.

III. Applications:

H07Z-K cables find extensive applications across various sectors due to their unique characteristics:

- Building Wiring:

The cables are commonly used in building wiring for power distribution, lighting, and other electrical installations. Their flame-retardant and halogen-free properties make them suitable for enhancing overall safety in residential and commercial buildings.

- Industrial Installations:

In industrial settings, where flexibility, flame retardance, and resistance to harsh conditions are paramount, these cables are deployed for powering machinery, control systems, and other applications.

- Data Centers:

The flexibility of H07Z-K cables, combined with their flame-retardant nature, makes them suitable for wiring in data centers. They can be efficiently routed and installed in the confined spaces often found in data center environments.

- Renewable Energy Projects:

These cables are used in renewable energy projects, such as solar and wind installations. Their resistance to UV radiation ensures durability in outdoor settings, and their halogen-free composition aligns with environmental standards.

- Transportation Sector:

Employed in the transportation sector, including railways and airports, for various electrical applications, their fine-wire stranding allows flexibility, making them suitable for installations in vehicles and transit systems.

IV. Compliance Standards:

H07Z-K cables adhere to international and national standards to ensure quality, safety, and compatibility. Common standards include:

- Harmonized Standards (HAR):

These cables often comply with harmonized standards recognized across European countries, ensuring they meet specific criteria for performance, safety, and environmental impact.

- IEC Standards:

International Electrotechnical Commission (IEC) standards may be applicable to H07Z-K cables, providing guidelines for their design, manufacturing, and testing processes.

- National Electrical Codes:

Depending on the region, these cables must comply with respective national electrical codes and regulations to ensure safe and legal use in various applications.

V. Installation Considerations:

In addition to their unique characteristics and applications, H07Z-K cables come with considerations for proper installation. The fine-wire stranding allows for easy bending and routing, but installers should adhere to recommended bending radii to prevent damage to the cable. Proper support and protection are essential, especially in environments where the cables might be exposed to mechanical stress or abrasion.

VI. Environmental Impact:

The halogen-free and flame-retardant nature of these cables not only ensures safety but also aligns with sustainability goals. Their absence of halogens means that in case of a fire, the cables won’t emit toxic gases, making them a responsible choice for environmentally conscious projects.

VII. Continued Advancements:

As technology progresses, ongoing research and development in cable materials may lead to further enhancements in H07Z-K cables. Innovations in insulation materials, conductor technology, and manufacturing processes could result in even more efficient and environmentally friendly cables. Keeping abreast of these advancements is crucial for industries aiming to benefit from the latest technologies in electrical installations.

VII. Global Adoption:

H07Z-K cables have gained widespread acceptance globally due to their reliability and compliance with international standards. Professionals across continents trust these cables for various applications, contributing to their global adoption. This universal acceptance underscores the cables’ versatility and performance across diverse environments and industry requirements.

Conclusion:

In conclusion, H07Z-K cables stand out in the realm of electrical wiring due to their halogen-free composition, flame retardance, thermosetting insulation, fine-wire stranding, and other key characteristics. These cables find versatile applications across industries, contributing to enhanced safety, flexibility, and reliability in electrical installations. Compliance with international standards further underscores their quality and suitability for a wide range of projects. As technological advancements progress, these cables are likely to evolve, maintaining a pivotal role in modern electrical systems. Understanding these key features empowers professionals to make informed decisions, ensuring optimal performance and safety in diverse applications.