If you’re in the market for UL cables, there are a few things you need to know. Standard UL cables are designed to meet specific safety standards, so it is important to choose the correct type for your application. Also, you need to make sure you order the correct gauge and length to meet your needs.

Introduction

1. What is it?

Standard UL cable is a type of cable used in various applications. It is frequently used in homes and businesses and is known for its quality and reliability. Certified by Underwriters Laboratories, which is why it is often referred to as a UL cable.

2. How is it made?

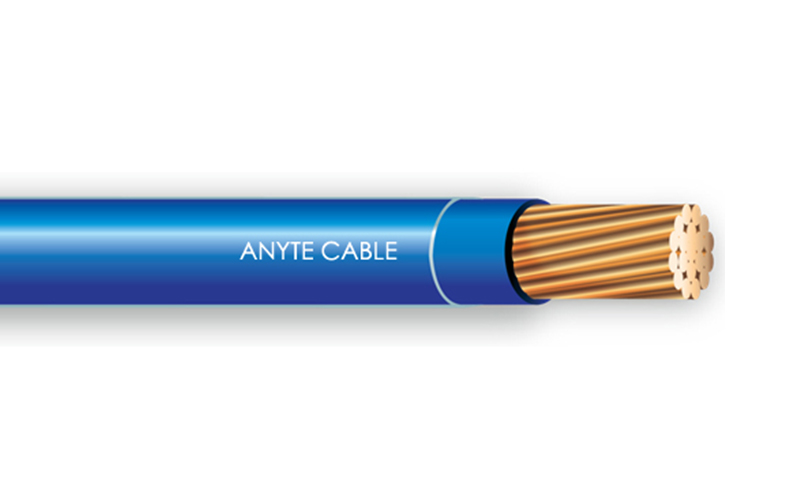

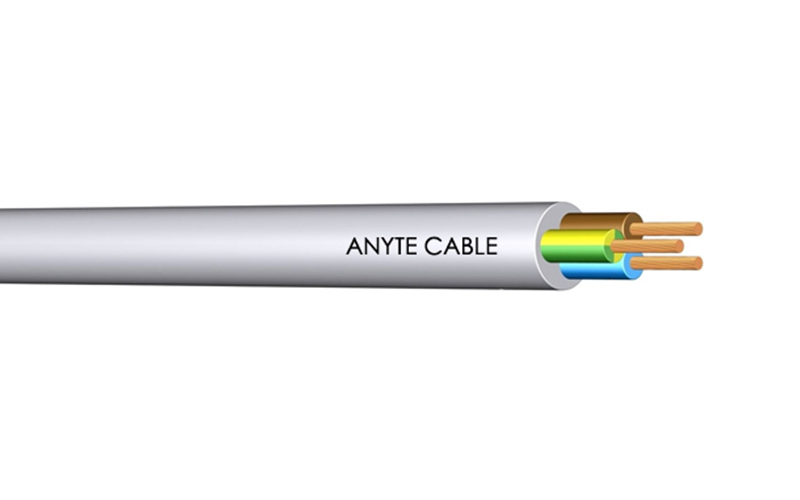

The cable is a cable certified by the UL (Underwriters Laboratories) organization. It’s made by combining multiple wires together and wrapping them in a protective sheath. Jackets are made from a variety of materials, depending on the intended use of the cable.

3. What are the benefits?

ANYTE UL cables are a great choice for those looking for safe and reliable electrical installations. UL cables are made from high-quality materials and undergo rigorous safety testing to ensure they meet the highest standards. This makes UL cables an excellent choice for both home and commercial applications.

What are the benefits of Standard UL cable?

1. safe

Because it has been certified by a third-party agency. This means the cable has been tested and complies with safety standards set by the UL organization. It’s also flame retardant, which means it won’t catch fire easily.

2. Reliable

UL cable is a type of cable used to transmit electricity. It is reliable and efficient. It is also safe and has a long service life.

3. Durable

Standard UL cable is a cable known for its durability. This type of cable is often used in commercial and industrial environments where it is subject to a great deal of wear and tear. It’s also known for its safety features, which make it a good choice for use in homes and other places where people might be present.

4. Affordable price

An excellent choice for your electrical wiring projects as it is affordable and complies with all safety standards. The cables are also available in a variety of colors so you can choose the one that best suits your project.

5. Easy to install

One of the benefits of using it is ease of installation. This is due to the light weight and low profile of the cables. In addition, the cables are flame retardant, so they are safe to use in any environment.

What are the different types?

1. Different types

There are three main types of durable UL cables: power, control and signal. Each type has different applications and purposes.

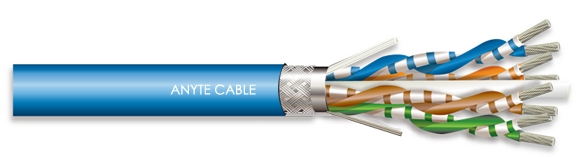

Power cables are used to deliver power to devices and devices. It is usually made of copper or aluminum and can be insulated or uninsulated. Control cables are used to transmit signals and commands between the device and the control panel. It’s usually made of copper and shielded from interference. Signal cables are used to transfer data, video, and other signals between devices. It’s usually made of copper and shielded from interference.

There are several different types of UL cables. The most common type is the W-cable. This cable is used for general wiring and is available in stranded and solid versions. Type W cables are also available in fire rated flame retardant versions. Another type of UL cable is the Type S cable. Designed for signage applications, this cable is available in stranded and solid versions.

2. Durability

There are different types of cables, each with its own advantages. Some of the advantages of UL cables include their flame retardancy, heat resistance and durability. Also approved for a variety of applications, making it a versatile choice for your needs.

The most common types of applications

- UL1426 cables are designed for general purpose wiring applications. It’s rated for 90 degrees Celsius and can be used in both dry and wet locations.

- UL1685 cables are designed for direct burial applications. It’s rated for 105 degrees Celsius and can be used in both wet and dry locations.

- UL1690 cables are designed for conduit and pipe applications. It’s rated for 75 degrees Celsius and can be used in both wet and dry locations.

- UL1703 cables are designed for use in hazardous locations. It’s rated for -40 degrees Celsius and should only be used in dry locations.

- UL854 cables are designed for power and control applications. It’s rated for 90 degrees Celsius and can be used in both wet and dry locations.

- UL870 cables are designed for signal and data applications. It’s rated for 75 degrees Celsius and can be used in both wet and dry locations.

How to Install Standard UL Cables

1. Installation method

Installing cables the correct way is very important to the safety of you and your loved ones. Here are some tips to help you get the job done right:

- Make sure you have all the necessary tools and supplies before starting.

- Read the installation instructions carefully before starting.

- Be careful when handling the wires.

- Make sure the cables are properly secured and there is no danger of them coming loose.

- Test the cables after installation to make sure they are working properly.

2. What is needed for installation

UL cable is a cable certified by Underwriters Laboratories. To install, you’ll need some basic tools and supplies. First, you’ll need a cable cutter to cut the cable to the correct length. You’ll also need a wire stripper to remove the insulation from the cable. Finally, you’ll need a pair of pliers to twist the wire harness together.

There are several steps to install properly. The first step is to strip the cable. You need to cut off the outer jacket of the cable. Next, you’ll need to cut the insulation off the individual wires. You can then use a stripper to remove the insulation from the tip of the wire.

Must be properly connected to work properly. There are a few different ways to do this, but the most common is to use a connector. This connector can be attached to one end of the cable, and then the other end can be attached to the device or devices you use it on. Make sure the connectors are properly aligned, then tighten the screws to secure them in place.

To terminate a Standard UL cable, you must first strip the cable’s jacket. Next, twist the wires together and plug them into the correct connectors. Finally, crimp the connectors onto the wires.

Related Products

UL SIS Cable