Flexible control cables play a vital role in numerous industries, offering enhanced functionality in environments where movement, flexibility, and durability are required. They are engineered for applications where traditional cables may not suffice due to the physical stress, continuous movement, or environmental challenges they face. These cables are commonly found in automation, robotics, manufacturing, and various industrial applications, and their versatility allows them to be adapted to a wide range of uses.

Understanding Flexible Control Cables

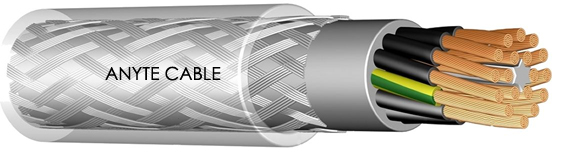

They are specialized cables designed to transmit control signals and power to equipment and machinery while withstanding constant bending, twisting, and mechanical stress. They typically consist of multiple cores made from fine copper strands that are tightly insulated and encased in durable outer sheathing. The primary purpose of these cables is to provide reliable electrical communication between different components of a system while maintaining flexibility and durability in dynamic applications.

Key Features of Flexible Control Cables:

- High Flexibility: These cables are made with fine copper strands and flexible insulation materials to allow for repeated bending without damage.

- Mechanical Strength: The outer sheathing is often made from durable materials such as PVC, rubber, or polyurethane, providing protection against abrasion, chemicals, and moisture.

- Electrical Stability: They are engineered to maintain consistent electrical performance despite movement, ensuring reliable signal transmission.

- Resistance to Environmental Factors: Many flexible control cables are designed to resist environmental factors such as extreme temperatures, UV radiation, chemicals, oils, and other corrosive substances.

Key Uses of Flexible Control Cables

1. Industrial Automation and Robotics

One of the most significant uses of it is in industrial automation and robotics. In these environments, machines and robotic arms must move continuously to perform complex tasks. They ensure that electrical signals and power are transmitted reliably, even as the cables undergo constant movement.

- Robotic Arms: Robotic systems often have joints that rotate and bend in multiple axes. They are required to transmit control signals and power from the control unit to the motors and sensors, without being damaged by the constant flexing.

- Automated Assembly Lines: In automated production lines, machines often require continuous electrical and data connections to control motors, actuators, and sensors. They ensure the necessary connectivity while withstanding repetitive movements.

- CNC Machines: Computer numerical control (CNC) machines, which are used in manufacturing for cutting, milling, and drilling operations, rely on flexible control cables to provide precise control signals for the moving parts.

2. Conveyor Systems

Conveyor systems in manufacturing plants and distribution centers rely heavily on flexible control cables to ensure smooth operation. These systems involve the continuous movement of materials along belts or rollers, and they often operate in harsh environments where the cables are exposed to dust, chemicals, and physical wear.

- Power Supply to Motors: They are used to supply power to the motors that drive the conveyor belts. As the belts move, the cables must remain flexible to prevent wear and tear, ensuring uninterrupted operation.

- Sensors and Automation: Conveyor systems also use sensors to detect the presence of items on the belt and automate the sorting or packaging process. They provide the necessary connections between the sensors, control units, and actuators to maintain smooth operations.

3. Cranes and Hoists

Cranes and hoists are essential equipment in industries such as construction, shipping, and manufacturing. They are used to lift and move heavy loads, often in environments where cables are subjected to constant bending, stretching, and twisting. They are ideal for such applications due to their ability to endure mechanical stress.

- Power and Signal Transmission: Cranes require flexible control cables to transmit power to the motors and control signals to the hoisting mechanisms. These cables must remain flexible and resistant to wear as the crane moves and operate in various directions.

- Control Pendant Systems: Control pendants, which are hand-held devices used to manage crane and hoist movement, rely on durable wiring for their operation. The cables allow the operator to move the control pendant freely without restricting movement or causing fatigue.

4. Elevator and Lift Systems

Elevators and lift systems also rely on flexible control cables to function efficiently and safely. In these applications, the cables must accommodate the continuous vertical movement of the elevator or lift while providing reliable electrical connections.

- Control and Power Cables: They are used to transmit signals from the control panel to the elevator motors and safety systems. They must maintain their integrity despite the constant bending and stretching as the elevator moves up and down.

- Communication Systems: Elevators often have built-in communication systems for emergencies, such as phones or intercoms. They are used to transmit voice signals, ensuring reliable communication between the elevator and external systems.

5. Equipamento médico

In the medical field, flexible control cables are used in various types of equipment that require precision and flexibility. Medical devices such as MRI machines, surgical robots, and patient monitoring systems need highly reliable and durable cables that can withstand constant movement while maintaining performance.

- Imaging and Diagnostic Equipment: They are used in medical imaging machines like MRIs and CT scanners, where they provide power and data connections. These cables must be resistant to electromagnetic interference (EMI) and must maintain their flexibility to prevent signal loss during movement.

- Surgical Robotics: In surgical robotic systems, they are used to transmit signals and power to the robotic arms and sensors. These cables must be highly flexible to allow for the precision movement required in surgeries.

6. Sistemas de energia renovável

The renewable energy sector, particularly in wind and solar power systems, relies on flexible control cables to handle the dynamic nature of these systems. Wind turbines and solar tracking systems require flexible cables that can withstand exposure to environmental conditions such as UV radiation, temperature fluctuations, and moisture.

- Wind Turbines: Wind turbines are used to transmit signals and power between the moving parts of the turbine, such as the blades and nacelle. These cables must endure the constant rotation of the turbine blades and the harsh outdoor environment.

- Solar Tracking Systems: Solar panels that use tracking systems to follow the sun throughout the day need flexible control cables to provide the necessary control signals and power to the tracking motors. These cables must be able to flex and twist as the panels move to optimize sunlight exposure.

7. Marine and Offshore Applications

In marine and offshore environments, they are widely used due to their resistance to harsh environmental conditions, including exposure to saltwater, humidity, and temperature extremes. These cables are commonly found in ships, offshore drilling platforms, and marine vessels.

- Shipboard Control Systems: They are used in shipboard control systems, where they provide power and control signals to various onboard equipment, such as navigation systems, communication devices, and propulsion systems.

- Offshore Oil Rigs: On offshore drilling platforms, they are used to control equipment such as cranes, hoists, and drilling machinery. These cables must be resistant to corrosion from saltwater and other environmental factors while maintaining flexibility and durability in harsh conditions.

8. Automotive and Transportation Systems

In the automotive and transportation sectors, flexible control cables are essential for various control systems, including those found in cars, trains, and airplanes. These systems require reliable electrical connections that can withstand vibrations, movement, and mechanical stress.

- Vehicle Wiring Harnesses: They are used in vehicle wiring harnesses to provide power and control signals to various components, such as lights, sensors, and control modules. These cables must be highly flexible to fit within tight spaces and endure constant vibration.

- Railway Signaling and Control Systems: In rail transport, they are used for signaling and control systems that ensure the safe operation of trains. These cables must be able to withstand the mechanical stress caused by vibrations and movements of the trains.

Conclusão

Flexible control cables are integral to a wide range of industries and applications due to their ability to withstand constant movement, mechanical stress, and challenging environmental conditions. From industrial automation and robotics to renewable energy and marine applications, these cables ensure the reliable transmission of signals and power, making them essential components in modern technology and industry. The key uses of flexible control cables span across various sectors, each requiring specialized solutions tailored to the unique demands of their operational environments.