In today’s world, where technology continues to advance at a rapid pace, the demand for high-performance cables has never been greater. Whether it’s for industrial applications, power distribution, or renewable energy projects, cables play a crucial role in ensuring reliable and efficient electrical connectivity. Among the myriad of cable options available, high-performance RV-K cables are steadily gaining recognition for their exceptional attributes. In this article, we will explore the key features that make high-performance RV-K cables stand out in the market.

1. Durability Beyond Expectations

High-performance RV-K cables are engineered for resilience. They are designed to withstand harsh environmental conditions, making them an ideal choice for outdoor and industrial applications. Their durability comes from the use of robust materials and a construction that can endure mechanical stress, abrasion, and extreme temperatures. This means that RV-K cables remain reliable and functional even in the face of challenging operating conditions.

2. Superior Insulation for Enhanced Safety

One of the standout features of high-performance RV-K cables is their exceptional insulation. These cables typically utilize advanced insulation materials, such as cross-linked polyethylene (XLPE) or ethylene propylene rubber (EPR). This insulation provides excellent resistance to electrical stress and minimizes the risk of electrical breakdown, ensuring the safety of both the cables and the connected systems.

The superior insulation properties of RV-K cables contribute to their longevity and ability to maintain consistent performance over time. This feature makes them a popular choice for critical applications in industries like power generation, renewable energy, and transportation.

3. Impressive Thermal Performance

Thermal performance is a vital aspect of any high-performance cable, and RV-K cables excel in this regard. The materials used in their construction are chosen for their ability to handle high temperatures without compromising electrical integrity. This thermal stability allows RV-K cables to function reliably in environments with elevated heat levels, making them suitable for industrial and power distribution applications where heat resistance is crucial.

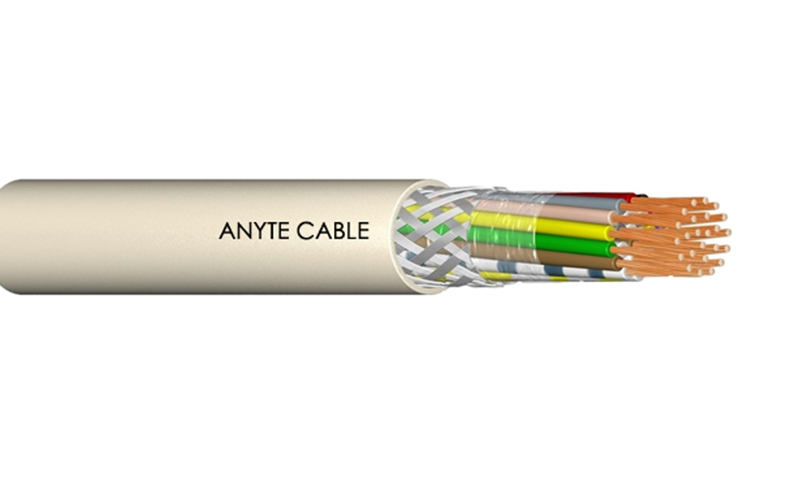

4. Versatile Range of Sizes and Configurations

High-performance RV-K cables are available in a wide range of sizes and configurations, ensuring that they can meet the specific requirements of various applications. Whether you need a single core or multicore cable, low voltage or medium voltage, or a specific conductor size, RV-K cables offer the versatility to accommodate diverse needs. This adaptability is a key feature that sets them apart in the market, as they can be customized to suit a variety of projects.

5. Resistance to Chemicals and Oils

In industrial and outdoor settings, exposure to chemicals and oils is a common challenge. High-performance RV-K cables are engineered to resist the harmful effects of these substances. They feature specialized jacket materials that provide resistance to a wide range of chemicals and oils, making them an ideal choice for applications in industrial environments, chemical plants, and petrochemical facilities.

6. Low Smoke Emission and Flame Retardancy

Safety is a top priority in many applications, especially those involving public spaces and enclosed environments. RV-K cables are designed with safety in mind. They are manufactured with materials that exhibit low smoke emission and excellent flame retardant properties. In the event of a fire, these cables produce minimal smoke, reducing the risk of harm to people and minimizing damage to property.

7. Environmental Friendliness and RoHS Compliance

As the world becomes increasingly conscious of environmental impact, high-performance RV-K cables comply with RoHS (Restriction of Hazardous Substances) regulations. These cables are free from hazardous substances such as lead, mercury, cadmium, and certain flame retardants, making them an environmentally responsible choice for various applications.

8. UV Resistance for Outdoor Applications

For applications in outdoor settings, such as solar power installations or overhead power distribution, exposure to ultraviolet (UV) radiation is a concern. RV-K cables are equipped with UV-resistant materials that protect them from the harmful effects of prolonged exposure to sunlight. This feature ensures that the cables remain reliable and safe in outdoor installations.

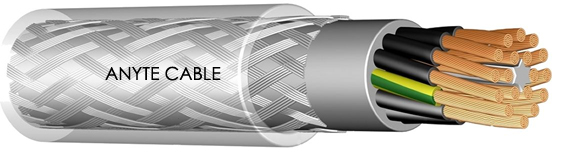

9. Excellent Mechanical Protection

High-performance RV-K cables are known for their mechanical strength and protection. Their sturdy construction includes multiple layers, such as insulation, metallic shielding, and jackets, that provide exceptional resistance to mechanical stress, impact, and vibrations. This mechanical robustness extends the cable’s lifespan and maintains its performance under challenging conditions.

10. Compliance with International Standards

High-capacity RV-K cables adhere to international standards and certifications, ensuring that they meet the strict requirements of different industries and applications. Compliance with standards such as IEC (International Electrotechnical Commission) and national regulations adds an extra layer of credibility and reliability to these cables.

Applications of High-Performance RV-K Cables

The exceptional features of high-capacity RV-K cables make them suitable for a wide range of applications, including:

- Projectos de energias renováveis: Solar farms and wind energy installations often require cables that can withstand outdoor exposure, UV radiation, and temperature fluctuations. RV-K cables are an excellent choice for connecting solar panels, inverters, and wind turbines.

- Industrial Environments: RV-K cables are commonly used in industrial settings where robust cables are needed to power machinery and equipment. Their resistance to chemicals, oils, and mechanical stress makes them ideal for manufacturing facilities and chemical plants.

- Power Distribution: These cables are frequently employed for power distribution in medium-voltage networks. Their durability and electrical performance ensure reliable electricity transmission.

- Transportation: RV-K cables are used in various transportation applications, including railways and airports, where safety and reliability are of utmost importance.

- Marítimo e Offshore: The resistance to harsh environmental conditions and mechanical stress makes RV-K cables suitable for marine and offshore applications, such as shipbuilding and oil rig installations.

- Infrastructure and Construction: RV-K cables are used in infrastructure projects and construction sites where they provide electrical connectivity for a range of applications, from lighting to heavy machinery.

The Future of High-Performance RV-K Cables

As technology advances and industries continue to evolve, the demand for reliable and durable cables like RV-K is expected to grow. These cables will play a vital role in supporting the expansion of renewable energy projects, the modernization of power distribution systems, and the development of smart cities.

The key features that set high-performance RV-K cables apart in the market are the result of extensive research and development in materials, manufacturing processes, and design. They are a testament to the commitment of cable manufacturers to provide reliable and high-quality solutions for a wide range of applications.

In the coming years, we can expect further innovations and refinements in the design and performance of RV-K cables. These developments will not only enhance their durability and reliability but also make them more adaptable to emerging technologies and applications. High-performance RV-K cables are set to remain a cornerstone of electrical connectivity, providing the backbone for numerous industries and contributing to a safer, more efficient, and more sustainable future.

In conclusion, high-performance RV-K cables are not just cables; they are technological marvels that empower the world’s critical infrastructure. Their durability, insulation, thermal performance, versatility, and compliance with international standards make them indispensable in an ever-evolving world where reliable electrical connectivity is non-negotiable.