序章

概要 PURケーブル PUR (ポリウレタン) ケーブルは、優れた耐久性、柔軟性、耐摩耗性で知られており、要求の厳しいさまざまな用途に最適です。これらのケーブルは、産業機械、ロボット工学、屋外設備など、機械的ストレス、化学物質、極端な温度が存在する環境で一般的に使用されます。PUR ケーブルの堅牢な構造は、過酷な条件下でも信頼性の高い性能を保証し、多くの産業で人気のある選択肢となっています。

適切なケーブルを選択することの重要性 特定のアプリケーションに適切なケーブルを選択することは、最適な性能と寿命を確保するために非常に重要です。適切なケーブルを使用することで、機器の効率性と信頼性を大幅に向上させることができますが、間違った選択をすると、頻繁なメンテナンスの問題、ダウンタイム、およびコストの増加につながる可能性があります。各アプリケーションに固有の要件とその利点を理解することは、十分な情報に基づいた決定を下す際に役立ち、選択したケーブルが環境と使用条件の要求を満たすことを保証します。

セクション1:PURケーブルについて

定義と構成

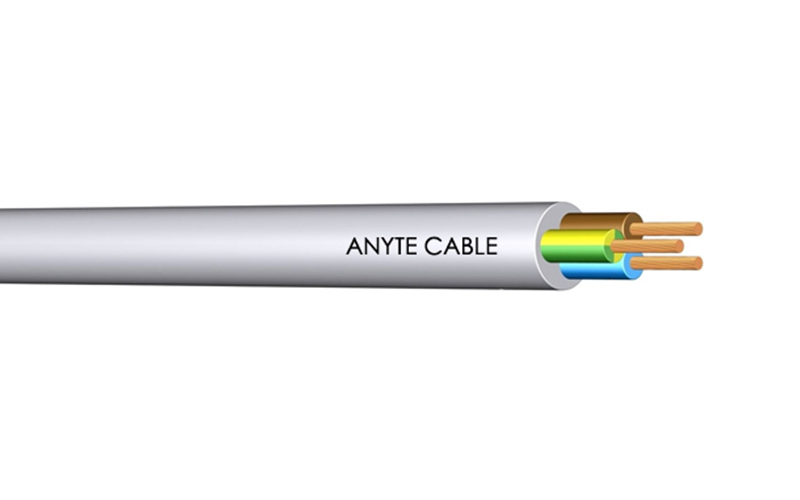

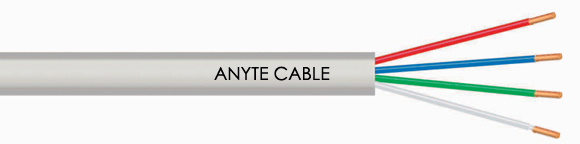

PUR(ポリウレタン)ケーブルは、多用途で弾力性のあるポリマーであるポリウレタン製のシースに包まれた電気ケーブルです。この素材は、高い引張強度、柔軟性、耐摩耗性、耐薬品性、極端な温度などの優れた機械的特性で知られています。PUR ケーブルの構成は、通常、銅またはアルミニウム導体のコアを絶縁材料で囲み、外側の PUR ジャケットで強固な保護と耐久性を提供します。

主なメリット

- 柔軟性: その際立った特徴のひとつは、卓越した柔軟性である。このため、ロボット工学、オートメーション・システム、ベルトコンベヤーなど、絶えず動いたり、曲がったり、屈曲したりする用途に最適です。PUR ケーブルの柔軟な性質により、破損することなく連続的な動的ストレスに耐えることができます。

- 耐久性がある: このケーブルは長寿命で有名です。ポリウレタン・ジャケットは耐摩耗性に優れ、過酷な産業環境での使用に適しています。物理的な衝撃、繰り返しの使用、乱暴な扱いにも、完全性を損なうことなく耐えることができます。

- 過酷な環境への耐性: PUR ケーブルはその堅牢な構成により、さまざまな環境要因に高い耐性を持つ。油、化学薬品、紫外線、高温と低温の両方の極端な温度への暴露に耐えることができます。この耐性により、屋外設備、製造工場、化学処理施設などの厳しい環境において、信頼性の高い性能と長寿命が保証される。

厳しい環境下で優れた性能を発揮するように設計されています。その柔軟性、耐久性、過酷な条件への耐性により、多くの産業用および商業用アプリケーションに好まれ、長期にわたって効率性と信頼性を保証します。

第2節 応募資格

環境条件

- PUR ケーブルを選択する際には、それがさらされる環境条件を考慮することが不可欠です。温度、湿度、化学薬品への暴露、紫外線放射などの要因は、ケーブルの性能と寿命に大きな影響を与えます。極端な温度にも耐えられるように設計されているため、高温と低温の両方の環境に適しています。さらに、化学薬品や紫外線に対する耐性があるため、過酷な産業環境や屋外用途でも機能性と信頼性を維持することができます。アプリケーションの特定の環境要件に適合する PUR ケーブルを選択することは、耐久性と安定した性能を確保するために非常に重要です。

機械的ストレス

- 機械的ストレスもケーブル選択の重要な要素です。ケーブルは、曲げ、ねじれ、摩耗に対する優れた耐性で知られており、反復的な動きや物理的ストレスを伴う用途に最適です。例えば、ケーブルが頻繁に曲げられるロボットや機械では、劣化することなく絶え間ない動きに耐えることができます。早期故障を防ぎ、長期的な信頼性を確保するためには、アプリケーションの機械的要求に対応できるケーブルを選択することが重要です。

電気的性能

- 定格電圧、電流容量、シールド要件など、ケーブルの電気的仕様は、安全で効率的な運用を確保するために不可欠です。ケーブルは、さまざまな電気的ニーズを満たすために、さまざまな構成で提供されています。大電力アプリケーションの場合、ケーブルが適切な定格電圧と電流容量を持つことを確認することは、過熱と潜在的な危険を防ぐために不可欠です。さらに、電磁干渉 (EMI) から保護するためにシールドが必要な場合もあります。アプリケーションの電気的性能基準を満たす PUR ケーブルを選択することで、安全性と効率の両方を確保できます。

第3節:業界特有の考慮事項

産業オートメーション

- 産業用オートメーションでは、ロボット、コンベアシステム、および機械装置の要求が高いため、ケーブルに対する要件は厳しい。ケーブルは非常に柔軟で機械的ストレスに強いため、これらの用途に特に適しています。劣化することなく連続的な動きや曲げに耐えることができるため、ロボットアームや自動機械での使用に最適です。さらに、耐油性、耐薬品性、耐摩耗性にも優れているため、過酷な産業環境でも長期にわたって性能を発揮します。

医療・ヘルスケア

- 医療・ヘルスケア分野では、ケーブルは厳しい衛生・安全基準を満たす必要があります。ケーブルは生体適合性が高く、滅菌が容易なため、医療機器や装置に最適です。これらのケーブルは、医療現場で一般的に使用される化学薬品や消毒剤に耐性があり、長期間にわたって安全性と機能性を維持することができます。さらに、PUR ケーブルの柔軟性と耐久性は、信頼性と安全性が最優先される画像機器から患者監視システムまで、さまざまな医療用途での使用に適しています。

屋外および海洋用途

- 屋外および海洋用途では、ケーブルは水、塩、および極端な気象条件への曝露に耐える必要があります。これらの課題を念頭に設計されたケーブルは、優れた耐水性と紫外線からの保護を提供します。このため、照明、看板、監視システムなどの屋外設備や、海水や過酷な天候にさらされる海洋環境での使用に最適です。堅牢な構造により、最も過酷な条件下でも完全性と性能を維持し、信頼性の高い長期的な接続性を実現します。

第4節 規制と安全基準

規格の遵守

- PUR ケーブルを選択する際には、関連する業界標準と認証に準拠していることを確認することが不可欠です。これらの規格は、ケーブルが特定の性能、安全性、および品質基準を満たしていることを保証するものです。例えば、UL (Underwriters Laboratories) 規格に適合している必要があります。これは、ケーブルが安全性と信頼性についてテストされていることを証明するものです。さらに、品質管理の ISO 9001 や環境管理の ISO 14001 などの ISO (国際標準化機構) 認証は、高品質で環境に配慮した製品を製造するというメーカーのコミットメントを示す重要な指標です。これらの規格に準拠することで、意図された用途で効果的かつ安全に機能することが保証されます。

安全への配慮

- PUR ケーブルを選択する際、安全性は非常に重要な要素である。重要な側面のひとつは耐火性で、ケーブルは火災の危険を最小限に抑えるよう設計され、緊急時に炎が広がるのを防ぐ必要がある。無毒性も重要な安全機能で、ケーブルが高温や火災にさらされても有害物質を放出しないことを保証する。さらに、化学物質や油に対する耐性も必要であり、過酷な環境下での劣化や潜在的な故障を防ぐことができる。PUR ケーブルにこれらの安全機能が組み込まれていることを確認することで、機器と人員の両方を保護することができ、さまざまな用途で信頼できる選択肢となります。

第5節:コストと寿命

コスト分析

- 他のタイプと比較してそのコストを評価する場合、初期投資と長期的な節約の両方を考慮することが不可欠です。PUR ケーブルは、標準的な PVC やゴム製のケーブルよりも初期費用は高いかもしれませんが、優れた耐久性と過酷な環境に対する耐性により、長期的には大幅な節約につながります。PUR ケーブルは、機械的ストレス、化学物質、極端な温度に耐えるように設計されているため、交換や修理の必要性が減ることで、初期投資を相殺することができます。そのため、高い初期費用は長期的な性能と信頼性によって正当化されることがよくあります。

耐久性とメンテナンス

- 耐久性は、最も重要な利点のひとつである。長寿命で知られ、要求の厳しい用途では他のタイプのケーブルよりも長持ちすることが多い。頑丈な構造であるため、摩耗や損傷に悩まされる可能性が低く、メンテナンスの頻度とコストを削減できます。さらに、過酷な条件にも耐えられるため、長期間にわたって機能的で効率的な状態を保つことができます。定期的な点検や適切な取り扱いなど、適切なメンテナンスを行うことで、さらに寿命を延ばすことができ、長年にわたって信頼性の高いサービスを提供することができます。

結論

PUR ケーブルを選択する際には、最適な性能と寿命を確保するためにいくつかの重要な要素を考慮することが極めて重要です。卓越した耐久性、柔軟性、過酷な環境に対する耐性により、産業オートメーション、医療、ヘルスケア、屋外および海洋環境での要求の厳しいアプリケーションに最適な選択肢となります。初期コストは高くなりますが、長期的な節約とメンテナンスの必要性の低減により、投資を正当化することができます。関連する安全規格および業界規格への準拠を保証することで、ケーブルの信頼性と安全性がさらに保証されます。環境条件、機械的ストレス、および電気的性能要件を慎重に評価することで、機器の効率と信頼性を高める情報に基づいた決定を下すことができます。適切なケーブルを選択することで、耐久性と信頼性の高い接続性が得られ、アプリケーションの成功が保証されます。