introduzione

Tray cables are a type of electrical cable used primarily in industrial and commercial applications for power distribution, control, and signal transmission. These cables are designed to be installed in cable trays, raceways, and outdoor locations, providing a robust solution for managing and protecting electrical wiring.

They play a critical role in various industries, including manufacturing, energy, and construction. Their importance lies in their ability to handle high power loads, resist harsh environmental conditions, and simplify the process of cable management. With their durability and versatility, they ensure reliable electrical performance and safety, making them an essential component in modern industrial and commercial infrastructure.

1. Power Tray Cables (Type TC)

Description and Construction

They are a versatile and robust type of cable designed to provide reliable power distribution. These cables are typically constructed with a combination of copper conductors, insulation, and protective jackets. The copper conductors ensure excellent electrical conductivity, while the insulation, often made of materials like PVC or XLPE, provides superior electrical isolation and heat resistance. The outer jacket protects the cable from environmental factors such as moisture, chemicals, and physical abrasion, making it suitable for demanding applications.

Common Applications

- Power Distribution in Industrial Settings

Type TC cables are widely used in industrial settings for power distribution. Their durable construction and ability to handle high voltage and current levels make them ideal for powering heavy machinery, motors, and other industrial equipment.

- Use in Control Circuits

These cables are also commonly employed in control circuits. Their reliable performance ensures accurate control and automation in industrial processes, enhancing operational efficiency and safety.

- Suitable Environments (Indoor, Outdoor, Direct Burial, etc.)

Power Tray Cables (Type TC) are designed for versatility and can be used in various environments: - Indoor: Ideal for indoor installations in cable trays, conduits, and raceways, providing a neat and organized solution for power distribution.

- Outdoor: With their robust construction and protective jackets, Type TC cables are suitable for outdoor applications, resisting UV radiation, moisture, and extreme temperatures.

- Sepoltura diretta: These cables can be directly buried underground, offering a reliable solution for underground power distribution without the need for additional protective conduits.

They are a reliable choice for various applications, offering durability, flexibility, and excellent performance in a wide range of environments.

2. Instrumentation Tray Cables (Type ITC)

Description and Construction:

Instrumentation Tray Cables (Type ITC) are specifically designed for the transmission of signals between equipment in industrial settings. These cables are typically constructed with multiple conductors, each insulated to prevent signal interference. The conductors are often shielded with a metallic layer to protect against electromagnetic interference (EMI) and encased in a robust outer jacket to withstand harsh environmental conditions. The materials used for insulation and jacketing can vary depending on the required specifications for resistance to chemicals, temperature, and mechanical stress.

Common Applications:

- Connection of Instrumentation and Control Equipment: Type ITC cables are widely used to connect various instrumentation and control devices, such as sensors, transmitters, and control panels. They ensure accurate and reliable signal transmission, which is crucial for process control and monitoring.

- Use in Signal Transmission: These cables are ideal for carrying low-voltage signals in industrial environments. They support data and voice communications, making them essential for systems that rely on precise and uninterrupted signal transmission.

- Suitable Environments: They are designed to perform reliably in demanding environments, including hazardous locations and industrial plants. They are often used in areas where exposure to chemicals, extreme temperatures, and mechanical stresses is common, ensuring both safety and durability in these challenging conditions.

3. Control Tray Cables (Type CIC)

Description and Construction

They are specifically designed for control circuits, featuring robust construction to withstand various environmental conditions. These cables typically consist of multiple stranded copper conductors insulated with high-quality thermoplastic or thermoset materials. The conductors are often twisted together and may include additional shielding to protect against electromagnetic interference. The outer jacket is usually made of PVC or other durable materials to ensure longevity and resistance to harsh conditions.

Common Applications

- Control Circuits: CIC cables are ideal for use in control circuits where precise operation and reliable performance are crucial. They are commonly found in systems requiring accurate control signals.

- Remote Control of Machinery and Equipment: These cables are used to transmit control signals for the remote operation of various machinery and equipment, ensuring smooth and efficient functioning.

- Suitable Environments:

- Industrial Control Panels: CIC cables are well-suited for installation in industrial control panels, where they facilitate the management and control of complex industrial processes.

- Conveyors: In environments such as conveyors, these cables provide reliable control for the movement and operation of the conveyor systems, ensuring consistent performance.

They are essential in maintaining the functionality and efficiency of control systems across a range of industrial applications. Their durable construction and versatility make them a reliable choice for demanding environments.

4. Thermocouple Tray Cables

Description and Construction

They are specially designed for temperature measurement and control applications. They are constructed with high-quality materials to ensure accurate signal transmission and durability in harsh environments. These cables typically feature multiple pairs of thermocouple wires, each pair individually shielded, with an overall jacket that provides additional protection.

Common Applications

- Temperature Measurement and Control: Used extensively for precise temperature monitoring and regulation.

- Process Control Systems: Integral in systems where maintaining specific temperatures is crucial for operation.

- Suitable Environments: Ideal for high-temperature areas and chemical plants, where resistance to heat and chemical exposure is essential.

5. Multi-Conductor Tray Cables

Description and Construction:

Multi-conductor tray cables consist of multiple insulated conductors enclosed in a single outer jacket, often featuring additional shielding for protection against electrical interference.

Common Applications:

- Multiple Control and Instrumentation Functions: Ideal for complex control and instrumentation tasks, providing reliable performance in diverse systems.

- Use in Complex Wiring Systems: Suitable for intricate wiring systems that require efficient and organized cable management.

- Suitable Environments: Commonly used in commercial buildings and industrial plants due to their durability and adaptability to various environmental conditions.

6. Communication Tray Cables (Type CM)

Description and Construction:

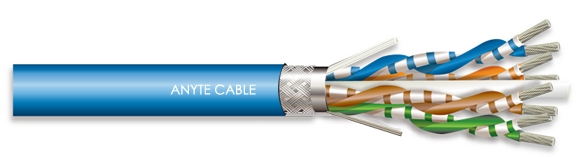

Communication tray cables (Type CM) are designed for data and signal transmission. They are constructed with multiple conductors, often shielded, to prevent interference and ensure signal integrity.

Common Applications:

- These cables are commonly used in communication networks, including offices, data centers, and security systems.

- Data Transmission: Type CM cables are engineered to support high-speed data transmission, making them ideal for modern communication needs.

- Use in Communication Networks: They are integral to the infrastructure of communication networks, ensuring reliable and efficient data flow.

- Suitable Environments: Communication tray cables are suitable for use in various environments such as offices, data centers, and security systems, where reliable data transmission is crucial.

Conclusione

In conclusion, tray cables play a crucial role in various industries due to their durability, flexibility, and ability to handle harsh environments. It’s important to select the right type of it for specific applications to ensure safety and efficiency. Looking ahead, advancements in technology are expected to further improve the performance and reliability of it, making them even more integral to modern electrical systems.