La selezione del tipo corretto di isolamento e rivestimento per il cavo in alluminio è fondamentale per garantire una trasmissione di potenza sicura ed efficiente. In questo articolo, discutiamo le varie opzioni disponibili per i tipi di isolamento e rivestimento e i fattori da considerare quando si sceglie l'opzione migliore per la propria applicazione specifica.

Tipi di isolamento dei cavi di alluminio durevoli

Cavi in alluminio sono disponibili in diversi tipi di isolamento, ciascuno con i propri vantaggi e svantaggi. I tipi di isolamento più comuni per i cavi in alluminio sono:

1.1 Cloruro di polivinile (PVC)

Il PVC è un tipo di isolamento molto diffuso per i cavi di alluminio perché è relativamente economico e fornisce un buon isolamento elettrico. Tuttavia, il PVC non è così resistente come altri tipi di isolamento e può diventare fragile nel tempo.

1.2 Polietilene reticolato (XLPE)

L'XLPE è un tipo di isolamento più durevole del PVC e viene spesso utilizzato in applicazioni in cui i cavi sono esposti a condizioni difficili. L'XLPE è anche più resistente agli agenti chimici e alle alte temperature rispetto al PVC.

1.3 Gomma etilene propilene (EPR)

L'EPR è un altro tipo di isolamento durevole, spesso utilizzato in applicazioni ad alta temperatura e ad alta tensione. L'EPR è anche più resistente all'ozono e ai raggi UV rispetto al PVC e all'XLPE.

_1661584667319.jpg)

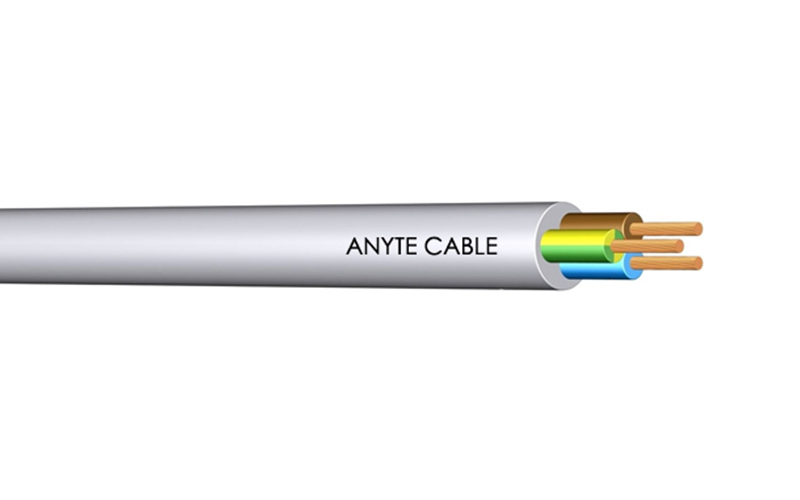

Alluminio Tipo di guaina del cavo

Oltre all'isolamento, il tipo di rivestimento di un cavo di alluminio svolge un ruolo importante per le sue prestazioni e la sua durata. I tipi più comuni di guaine per cavi di alluminio sono:

2.1 PVC

Il PVC è un tipo di guaina comune per i cavi di alluminio perché è relativamente economico e ha un buon isolamento elettrico. Tuttavia, il PVC non è così resistente come altri tipi di guaina e può diventare fragile nel tempo.

2.2 Polietilene (PE)

Il PE è un tipo di rivestimento più resistente del PVC e viene spesso utilizzato in applicazioni in cui il cavo è esposto a condizioni difficili. Il PE è anche più resistente agli agenti chimici e alle alte temperature rispetto al PVC.

2.3 Alogeni a basso contenuto di fumo (LSZH)

L'LSZH è un materiale ignifugo che emette pochissimo fumo e non produce alogeni tossici se esposto al calore o al fuoco. Per motivi di sicurezza, questo tipo di cavo resistente al fuoco La guaina è comunemente utilizzata negli edifici industriali, commerciali e residenziali, nonché nei sistemi di trasporto.

Fattori da considerare nella scelta del tipo di isolamento e di guaina

La scelta del tipo di isolamento e di rivestimento per il cavo di alluminio deve tenere conto di diversi fattori, tra cui:

3.1 Temperatura di lavoro

La temperatura di esercizio del cavo determina la temperatura massima a cui l'isolamento e la guaina possono operare in sicurezza. Ad esempio, il PVC ha una temperatura di esercizio massima di 60°C, mentre l'XLPE e l'EPR possono sopportare temperature fino a 90°C.

3.2 Tensione nominale

La tensione nominale del cavo determina la tensione massima a cui l'isolamento e la guaina possono operare in sicurezza. È importante scegliere un tipo di isolamento e di guaina con una tensione nominale pari o superiore a quella del cavo.

3.3 Condizioni ambientali

Anche l'ambiente in cui il cavo verrà installato avrà un ruolo importante nel determinare il tipo di isolamento e rivestimento migliore. Ad esempio, se il cavo sarà esposto a radiazioni chimiche o ai raggi UV, è importante scegliere un tipo di isolamento e di rivestimento in grado di resistere a queste condizioni.

3.4 Norme di sicurezza e antincendio

Oltre ai fattori sopra citati, anche le norme di sicurezza e antincendio giocano un ruolo fondamentale nel determinare il miglior tipo di isolamento e guaina. Ad esempio, se il cavo sarà installato in un edificio o in un sistema di trasporto, potrebbe essere auspicabile utilizzare un tipo di guaina resistente alle fiamme, che emetta un fumo minimo quando esposto al calore o al fuoco e che non contenga alogeni tossici, come la AWM UL2464.

3.5 Durata e manutenzione

Nella scelta del tipo di isolamento e di guaina si deve tenere conto anche della durata e dei requisiti di manutenzione del cavo. Ad esempio, l'XLPE e l'EPR sono più durevoli del PVC e possono richiedere meno manutenzione nel corso della vita del cavo.

Insomma

La scelta del tipo corretto di isolamento e di rivestimento per i cavi in alluminio è fondamentale per garantire una trasmissione di energia sicura ed efficiente. I tipi di isolamento più comuni per i cavi in alluminio includono PVC, XLPE e EPR, mentre i tipi di rivestimento più comuni includono PVC, PE e LSZH. Quando si sceglie l'opzione migliore per una particolare applicazione, è importante considerare fattori quali la temperatura di esercizio, la tensione nominale, le condizioni ambientali, le norme di sicurezza e antincendio, la durata e la manutenzione. Con il tipo di isolamento e di guaina corretti, il vostro cavo di alluminio sarà in grado di funzionare al massimo delle sue potenzialità, fornendo una trasmissione di energia affidabile ed efficiente per gli anni a venire.

Informazioni aggiuntive

Quando si sceglie il tipo di isolamento e di rivestimento per il cavo di alluminio, è bene consultare un esperto che possa guidarci nella giusta direzione. È inoltre importante consultare le norme di sicurezza e antincendio, che possono variare a seconda del luogo, dell'applicazione e del settore industriale. Assicuratevi sempre che il tipo di isolamento e di rivestimento scelto soddisfi i requisiti del National Electrical Code (NEC) e di altri standard pertinenti della vostra zona. Con il tipo di isolamento e la guaina corretti, i cavi in alluminio garantiscono una trasmissione sicura, affidabile ed efficiente dell'energia, essenziale per qualsiasi sistema elettrico.

Qualsiasi cavo non solo sviluppa e produce cavi standard di alta qualità, ma fornisce anche soluzioni eccellenti in base alle vostre esigenze e alle applicazioni del prodotto. Accogliamo con piacere la vostra richiesta in qualsiasi momento.

prodotti correlati