Ⅰ. Introduce

PUR cable multi-core is a cable with multiple conductors. It can carry more current and is therefore suitable for high power applications. Multi-conductor cables also have better protection properties, so they can also be used in high-voltage or high-temperature environments. In the practical application of multi-core cables, the following issues should be paid attention to: 1. Select the type and specification of the cable according to the application. 2. Try to avoid contact with other objects during installation and use. 3. When connecting wires, it is best to use special insulating materials. 4. If the cable fails, it can be repaired by using the corresponding maintenance method.

Whether in domestic, commercial or industrial applications, PUR cable multi-core is a premium multi-purpose cable. The advantage of this product lies in its wear resistance, voltage resistance, temperature resistance and high strength. It can be used in various occasions to meet the needs of various applications.

Ⅱ. Features of PUR multi-core cable

- Good durability, suitable for use in basements and harsh environments.

- The cable conductors are made of copper and aluminum alloy materials, which have excellent electrical properties.

- The cable sheath is made of PVC material, which is wear-resistant and corrosion-resistant.

- Different regional partitions can be performed as needed.

Ⅲ. PUR multi-core cable has the following characteristics

- PUR cable multi-core has good durability and is suitable for use in basements and harsh environments.

- The cable conductors are made of copper and aluminum alloy materials, which have excellent electrical properties.

- The PVC outer skin is made of wear-resistant and corrosion-resistant materials, which has a strong protective effect.

- Different regional partitions can be performed as needed.

Ⅳ. Advantages of PUR Multicore Cables

- PUR multi-core cable has the advantages of high temperature resistance, low temperature resistance, pressure resistance and electromagnetic interference resistance, and is suitable for high-voltage and large-capacity power transmission.

- PUR multi-core cables also have good insulation properties and can be used in harsh environments.

- Multi-core cables can be divided into single and multiple, and their models will be different according to different uses.

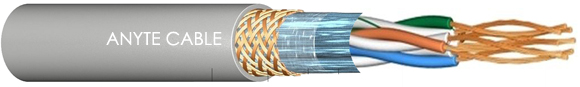

- मल्टीकोर केबलis made of multiple copper core conductors. It is generally composed of copper wires, control wires and insulating materials. According to the thickness of the conductive layer, it is divided into: single-layer multi-core cable (also known as single multi-core cable), double-layer multi-core cable and three-layer multi-core cable; according to the shielding layer The materials are divided into: aluminum alloy shielded cable and plastic shielded cable.

- PUR cable multi-core is mainly used in power supply system with AC 100V/500V, DC 1000V or DC voltage below 500V. It has a certain dielectric strength and can withstand high voltage and high current electrical equipment.

- Because the copper core conductor has a high electrical conductivity (about 10MJ/m2K-1), multi-core cables can be used for electrical equipment with high voltage requirements, high operating temperature and wide temperature variation range. as an insulated wire.

- When the use conditions are harsh, it can also be replaced by cables composed of multiple different types of multi-core conductors to meet the various special requirements of equipment and personnel on voltage and frequency.

Ⅴ. Application of PUR multi-core cable

- The use of PUR cable multi-core in the cold storage and power distribution room can effectively prevent the occurrence of fire, because the PUR multi-core cable has good flame resistance.

- PUR multi-core cables can be used in harsh working conditions, such as high temperature, humidity, salt spray, etc.

- PUR multi-core cables can be used in the transportation of various gases and liquids.

Ⅵ. Installation method of PUR multi-core cable

- Before laying the PUR cable multi-core cable, check whether the outer diameter and model of the cable match the requirements of the project.

- Cable laying should minimize bending, and in case of bending, it should be carried out within the minimum bending radius.

- Do not lay the cable in a cold, humid or heavily dusty place.

- Before laying the cable, put the protective cover on the cable terminal or connector.

- When laying the पुर मल्टी कोर केबल on a fixed object, fix the cable at one end first, and then fix the other end.

- Pay attention to cross-connection when laying multi-core cables.

- The cable laying method shall be determined according to the design drawings and the site conditions of the construction unit, and shall ensure safe, beautiful, convenient and reliable operation.

Ⅶ. Care and maintenance of PUR multi-core cables

1. Maintenance of PUR multi-core cables

PUR cable multi-core is composed of many native cores (single or multiple), so special attention should be paid during use. The service life of each original core wire is different, so regular inspection and maintenance are required.

2. Maintenance method of PUR multi-core cable

- Cleaning: When cleaning, use a clean cloth to wipe the surface of the cable to avoid using chemicals.

- Insulation: Insulation is generally achieved by spraying or compressing. If it breaks or is oxidized, it needs to be repaired.

- Encapsulation: Encapsulation is one of the important factors to ensure the service life of multi-core cables. PUR cable multi-core encapsulation should be checked regularly to avoid cracks, oxidation, blackening, and leakage.