Introduction

In the ever-evolving landscape of electrical engineering and infrastructure projects, the need for tailored solutions has become increasingly evident. One area where customization plays a pivotal role is in the realm of आरवी-कश्मीर cables. These versatile cables, known for their reliability and performance, are now being adapted to meet the unique requirements of specific projects. In this article, we will explore the trend of customization in electrical cables, delving into how they can be modified to address specific project needs. From insulation materials to conductor sizes and protective sheathing options, the possibilities are vast, offering enhanced flexibility and efficiency in a wide range of applications.

Understanding RV-K Cables

Before delving into the world of customization, it’s important to grasp the fundamentals of RV-K cables. These cables are primarily used for power distribution in various applications, including industrial, residential, and commercial settings. They are known for their durability, flexibility, and high-quality insulation, making them a reliable choice for a multitude of electrical installations.

The Trend of Customization

Customization in RV-K cables is driven by the recognition that no two projects are alike. Specific applications, environmental conditions, and project objectives necessitate cables that are tailored to meet these unique demands. Let’s explore the key aspects of customization in electrical cables cables:

1. Insulation Materials

One of the primary areas of customization lies in the selection of insulation materials. Different projects may require varying levels of insulation to withstand temperature extremes, environmental factors, and voltage requirements. For example, projects in harsh industrial environments may opt for cables with robust, high-temperature insulation, while residential projects may prioritize cost-effective but reliable insulation options.

2. Conductor Sizes

The size and configuration of conductors within RV-K cables can be customized to suit specific power transmission needs. Projects with high power demands may require larger conductor sizes to minimize voltage drop, while smaller conductors may be sufficient for lower-power applications. Customizing conductor sizes ensures optimal electrical performance.

3. Voltage Ratings

RV-K cables are available in various voltage ratings to accommodate different project requirements. Customizing the voltage rating ensures that the cable can safely and efficiently handle the specified electrical load. Projects involving high-voltage distribution grids will have different voltage requirements than those serving residential areas.

4. Protective Sheathing Options

Protective sheathing plays a crucial role in shielding RV-K cables from external factors such as moisture, chemicals, and physical damage. Customizing the sheathing material and design allows for enhanced protection tailored to the specific project’s environmental conditions. For instance, cables installed in underground applications may require extra protection against moisture and soil contaminants.

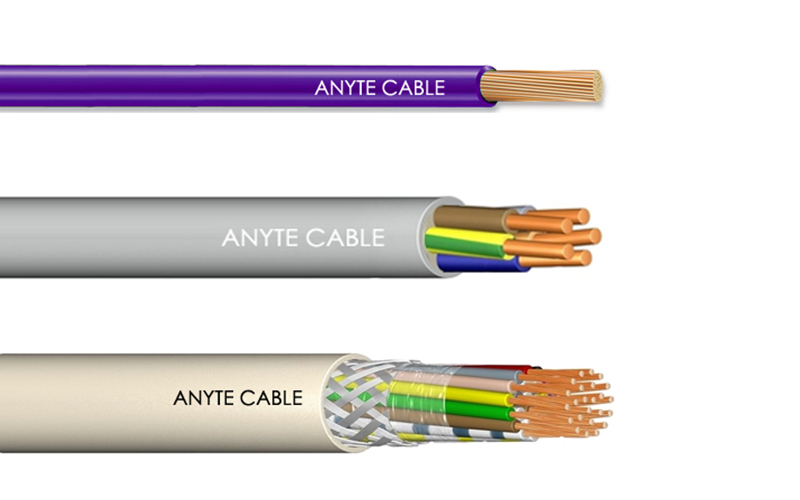

5. Color Coding and Identification

Customization can extend to color coding and identification features on the cable jackets. This is particularly valuable in complex installations where different cables serve distinct functions. Custom colors and markings simplify cable identification and reduce the risk of errors during installation and maintenance.

6. Compliance with Regulations

Customized RV-K cables must adhere to local and international electrical regulations and safety standards. Ensuring compliance is paramount to guaranteeing the safety and reliability of the electrical system.

Case Studies: Customization in Action

Let’s explore two hypothetical case studies to illustrate the real-world impact of customization in RV-K cables:

Case Study 1: Solar Farm Project

Imagine a large-scale solar farm project that spans a vast area with diverse environmental conditions. Customized RV-K cables are selected with robust UV-resistant insulation to withstand prolonged exposure to sunlight. Additionally, larger conductor sizes are chosen to minimize power loss over long transmission distances. The cables are color-coded to simplify installation, ensuring that each section of the solar farm is connected correctly. This level of customization optimizes the performance and longevity of the solar power distribution system.

Case Study 2: Industrial Plant Expansion

In an industrial plant expansion, electrical systems are subjected to demanding conditions, including temperature extremes and exposure to chemicals. Custom RV-K cables with specialized high-temperature and chemical-resistant insulation are deployed. These cables are designed to meet the project’s specific voltage requirements and are equipped with durable protective sheathing to withstand the industrial environment. Compliance with strict safety regulations is a top priority, ensuring the safety of personnel and equipment.

As we look to the future of customization in RV-K cables, it’s important to consider some emerging trends and potential developments in this field:

1. Smart Integration: With the rise of smart buildings and IoT (Internet of Things) applications, electrical cables may incorporate smart technology, such as embedded sensors for monitoring electrical performance and safety in real time. Customized electrical cables could become an integral part of intelligent electrical systems.

2. Enhanced Environmental Sustainability: As environmental concerns grow, there is a growing demand for eco-friendly materials and manufacturing processes. Customization may extend to selecting insulation materials that are not only performance-oriented but also environmentally responsible, contributing to sustainability goals.

3. Integration of Renewable Energy: electrical cables customized for renewable energy projects may become even more prevalent. These cables may need to accommodate unique installation requirements for solar panels, wind turbines, and energy storage systems, enabling efficient power transmission from clean energy sources.

4. Automation and Robotics: In industrial settings, where automation and robotics are on the rise, customized RV-K cables may be designed to withstand the rigors of dynamic machinery and repetitive motion. These cables could play a critical role in powering and controlling automated systems.

5. Energy Efficiency: Customized RV-K cables may be tailored to enhance energy efficiency by minimizing power losses during transmission. Innovative conductor materials and designs may be employed to reduce electrical resistance and improve overall system efficiency.

6. Integration with Smart Grids: As smart grids become more widespread, customized electrical cables may integrate seamlessly with these advanced electrical distribution systems. This integration could enable real-time monitoring, remote control, and optimization of power distribution.

7. Advanced Protective Sheathing: Protective sheathing options may continue to advance, offering enhanced resistance to extreme conditions such as fire, chemicals, and physical impact. Customized sheathing materials may be developed to ensure maximum safety and longevity in demanding environments.

8. Rapid Prototyping and 3D Printing: The advent of rapid prototyping and 3D printing technologies may enable quicker development and customization of RV-K cables. Engineers may have the flexibility to create prototypes and customized cables more efficiently, accelerating project timelines.

9. Energy Storage Integration: As energy storage systems become more prevalent, customized electrical cables may be designed to support the unique requirements of energy storage installations, including high currents and rapid charge-discharge cycles.

निष्कर्ष

Customization in RV-K cables is a growing trend that empowers project managers and engineers to tailor electrical infrastructure solutions to precise project requirements. From insulation materials to conductor sizes and protective sheathing options, the ability to customize electrical cables ensures optimal performance, reliability, and safety in diverse applications. As projects continue to evolve and demand unique solutions, the versatility of customized electrical cables will remain a vital asset in the field of electrical engineering and infrastructure development.