AWM UL2464 bezieht sich auf eine bestimmte Art von Draht- und Kabelnorm, die von Underwriters Laboratories (UL) festgelegt wurde. Sie definiert die Anforderungen und Spezifikationen für isolierte flexible Kabel, die für den allgemeinen Gebrauch in verschiedenen Anwendungen bestimmt sind, wobei der Schwerpunkt auf der Elektro-, Elektronik- und Telekommunikationsindustrie liegt. Das Verständnis der Eigenschaften, des Aufbaus und der Anwendungen dieser Kabel kann ihre Nutzung in verschiedenen Bereichen erheblich verbessern.

Überblick über AWM UL2464

AWM steht für "Appliance Wiring Material" (Geräteverdrahtungsmaterial), eine Kategorie, die eine Reihe von Drähten und Kabeln umfasst, die für die Stromübertragung in Geräten und Anlagen bestimmt sind. UL2464 ist eine Bezeichnung, die die Anforderungen für flexible, mehradrige Kabel mit einem Außenmantel festlegt, die typischerweise in Steuer-, Strom- und Signalanwendungen verwendet werden.

Wesentliche Merkmale

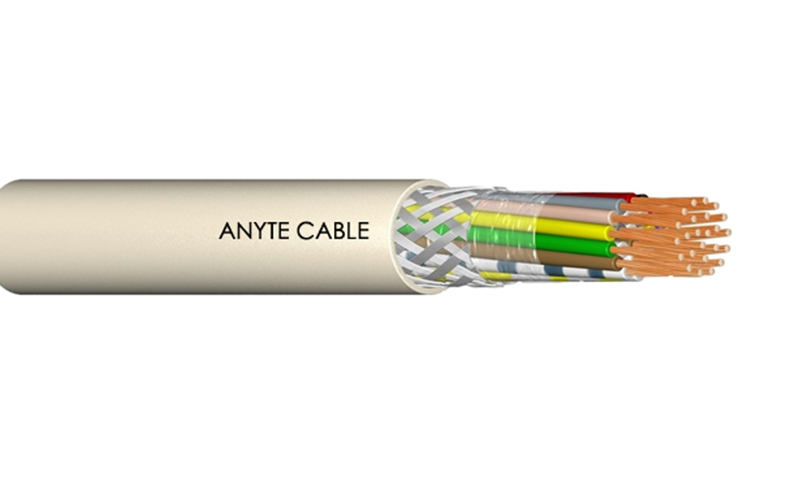

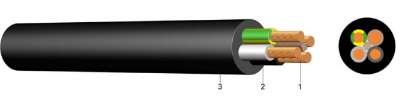

- Dirigenten: AWM UL2464-Kabel bestehen in der Regel aus verseilten Kupferleitern, die die Flexibilität und die einfache Installation verbessern. Die Leiter sind normalerweise verzinnt, um Oxidation zu verhindern und die Lötbarkeit zu verbessern.

- Isolierung: Die in AWM UL2464-Kabeln verwendeten Isoliermaterialien sind häufig thermoplastische oder duroplastische Polymere. Zu den gängigen Isoliermaterialien gehören PVC (Polyvinylchlorid) und XLPE (vernetztes Polyethylen). Diese Materialien bieten hervorragende dielektrische Eigenschaften und gewährleisten eine effiziente elektrische Leistung.

- Temperatur Bewertung: Je nach Isoliermaterial haben sie im Allgemeinen eine Temperaturbeständigkeit von 80°C (176°F) oder höher. Damit sind sie für eine Vielzahl von Umgebungen geeignet, auch für industrielle Umgebungen.

- Spannungswert: Die Standardspannung beträgt in der Regel 300 Volt, wodurch sie für verschiedene Nieder- und Mittelspannungsanwendungen geeignet sind.

- Flammbeständigkeit: Sie sind so konstruiert, dass sie bestimmte Anforderungen an die Flammbeständigkeit erfüllen, was bei Anwendungen, bei denen der Brandschutz eine Rolle spielt, entscheidend sein kann.

- Umweltresistenz: Je nach den verwendeten Isoliermaterialien können die Kabel auch gegen Feuchtigkeit, Chemikalien und UV-Licht beständig sein.

Anwendungen von AWM UL2464

Aufgrund ihrer Flexibilität, Langlebigkeit und Zuverlässigkeit werden sie in vielen verschiedenen Branchen eingesetzt. Nachstehend sind einige der wichtigsten Anwendungen aufgeführt:

1. Industrielle Automatisierung

In der Industrie werden sie in der Regel für den Anschluss von Sensoren, Aktoren und Steuergeräten verwendet. Ihre Fähigkeit, sowohl Strom als auch Signale zu übertragen, macht sie ideal für Automatisierungssysteme, bei denen mehrere Leiter für verschiedene Funktionen benötigt werden. Die Flexibilität dieser Kabel ermöglicht eine einfache Verlegung in Maschinen und engen Räumen.

2. Schalttafeln

Sie werden häufig in Schalttafeln für Maschinen und Anlagen eingesetzt. Sie stellen die notwendigen Verbindungen zwischen verschiedenen Komponenten her und gewährleisten einen zuverlässigen Betrieb. Die Isolationseigenschaften schützen vor elektrischen Störungen, was für die Aufrechterhaltung der Signalintegrität entscheidend ist.

3. Robotik

In Robotersystemen erleichtern AWM UL2464-Kabel die Kommunikation und Stromversorgung zwischen Steuereinheiten und Motoren. Die Flexibilität dieser Kabel ermöglicht Bewegungen, ohne die Integrität der Verbindungen zu beeinträchtigen. Dies ist besonders wichtig bei Anwendungen, bei denen Roboter in dynamischen Umgebungen arbeiten.

4. Telekommunikation

Sie werden in Telekommunikationsgeräten wie Routern, Switches und Servern eingesetzt. Sie stellen die notwendigen Verbindungen für die Datenübertragung und die Stromversorgung her und sorgen dafür, dass die Kommunikationssysteme effizient arbeiten.

5. Unterhaltungselektronik

Die Unterhaltungselektronik dient dazu, verschiedene Komponenten in Geräten wie Computern, Fernsehern und Audiogeräten miteinander zu verbinden. Ihre Zuverlässigkeit und Leistung sind entscheidend für die Funktionalität dieser Produkte.

6. Medizinische Ausrüstung

Sie kommen auch in medizinischen Geräten zum Einsatz, bei denen Zuverlässigkeit und Sicherheit an erster Stelle stehen. Diese Kabel können Stromversorgungen, Sensoren und Steuersysteme in medizinischen Geräten verbinden und gewährleisten, dass diese in sensiblen Umgebungen effektiv funktionieren.

7. Luft- und Raumfahrt und Verteidigung

In der Luft- und Raumfahrt und im Verteidigungsbereich werden sie für die Verkabelung von Avioniksystemen verwendet, bei denen Leistung und Zuverlässigkeit entscheidend sind. Aufgrund ihrer Fähigkeit, extremen Umweltbedingungen standzuhalten, eignen sich diese Kabel für Anwendungen in Flugzeugen und militärischer Ausrüstung.

8. Energie und Versorgungsunternehmen

Sie sind in der Energie- und Versorgungswirtschaft zu finden, wo sie für Überwachungs- und Kontrollsysteme eingesetzt werden. Ihre Fähigkeit, Signale und Leistung zu übertragen, macht sie für die Aufrechterhaltung des Betriebs verschiedener Energiesysteme unerlässlich.

Vorteile der Verwendung von AWM UL2464

- Flexibilität: Die verseilten Kupferleiter bieten außergewöhnliche Flexibilität und ermöglichen eine einfache Verlegung und Installation in engen Räumen.

- Dauerhaftigkeit: Die robusten Isoliermaterialien der AWM UL2464-Kabel gewährleisten Langlebigkeit und Verschleißfestigkeit und eignen sich daher für verschiedene Umgebungen.

- Vielseitigkeit: Sie können in einer Vielzahl von Anwendungen eingesetzt werden, von der industriellen Automatisierung bis hin zur Unterhaltungselektronik, was sie zu einer vielseitigen Wahl für Ingenieure und Hersteller macht.

- Sicherheit: Die Einhaltung der UL-Normen stellt sicher, dass die AWM UL2464-Kabel die strengen Sicherheits- und Leistungsanforderungen erfüllen, so dass die Benutzer beruhigt sein können.

- Leistung: Die hervorragenden elektrischen Eigenschaften der Kabel, einschließlich der geringen Kapazität und des minimalen Signalverlusts, machen sie ideal für Hochleistungsanwendungen.

Detaillierte Eigenschaften von AWM UL2464

Um die AWM UL2464 besser zu verstehen, ist es wichtig, sich mit ihren detaillierten Eigenschaften und Spezifikationen auseinander zu setzen. Diese Attribute stellen sicher, dass das Kabel in verschiedenen Anwendungen optimal funktionieren kann.

1. Leiter-Spezifikationen

Die Leiter in AWM UL2464-Kabeln bestehen in der Regel aus Kupfer, das wegen seiner hervorragenden elektrischen Leitfähigkeit bevorzugt wird. In den Kabeln werden häufig Litzenleiter verwendet, die aus mehreren kleinen, miteinander verdrillten Litzen bestehen. Diese Konstruktion erhöht die Flexibilität und verringert die Wahrscheinlichkeit von Brüchen bei der Installation oder Bewegung. Die Verzinnung der Kupferleiter verhindert die Oxidation, die die Leitfähigkeit im Laufe der Zeit verschlechtern kann.

2. Arten der Isolierung

Die in AWM UL2464-Leitungen verwendete Isolierung kann variieren, umfasst aber im Allgemeinen:

- Polyvinylchlorid (PVC): PVC wird aufgrund seiner Kosteneffizienz und seiner guten dielektrischen Eigenschaften häufig verwendet. Es ist für verschiedene Umgebungen geeignet, kann aber Einschränkungen hinsichtlich der Temperatur- und Chemikalienbeständigkeit aufweisen.

- Vernetztes Polyethylen (XLPE): XLPE bietet im Vergleich zu PVC bessere thermische und mechanische Eigenschaften und eignet sich daher ideal für Anwendungen, die eine hohe Leistung und Widerstandsfähigkeit erfordern.

- Thermoplastische Elastomere (TPE): TPE bietet eine hervorragende Flexibilität und Beständigkeit gegen extreme Temperaturen und ist daher für Anwendungen in rauen Umgebungen geeignet.

Jeder Isolationstyp verfügt über spezifische Eigenschaften in Bezug auf Temperaturtoleranz, chemische Beständigkeit und Flexibilität, die maßgeschneiderte Anwendungen auf der Grundlage von Umweltanforderungen ermöglichen.

3. Temperatur- und Spannungswerte

Die Temperaturklassen für AWM UL2464-Kabel sind im Allgemeinen in verschiedene Bereiche eingeteilt, in der Regel von -20°C bis 80°C (-4°F bis 176°F). Einige Spezialkabel können sogar höheren Temperaturen standhalten. Die Spannungsangabe, in der Regel 300 Volt, ist für Nieder- bis Mittelspannungsanwendungen ausgelegt und gewährleistet einen sicheren Betrieb unter bestimmten Bedingungen.

4. Mechanische Festigkeit und Flexibilität

Sie sind so konstruiert, dass sie mechanischen Belastungen während der Installation und Nutzung standhalten. Dank ihrer Flexibilität lassen sie sich biegen, ohne zu brechen, und eignen sich daher für dynamische Anwendungen, bei denen Bewegungen zu erwarten sind. Die robuste Konstruktion stellt außerdem sicher, dass die Kabel Biegungen und Verdrehungen standhalten, ohne die elektrische Integrität zu beeinträchtigen.

5. Flammwidrigkeit und Sicherheitsstandards

Bei elektrischen Kabeln steht die Sicherheit an erster Stelle. Sie können so konstruiert werden, dass sie verschiedene Flammschutznormen erfüllen, um sicherzustellen, dass sie im Falle eines Fehlers nicht zur Ausbreitung von Feuer beitragen. Die UL-Zertifizierung zeigt an, dass das Kabel strengen Tests unterzogen wurde, um die Sicherheitsnormen der Branche zu erfüllen, was Herstellern und Endnutzern gleichermaßen Sicherheit bietet.

6. Umweltresistenz

Sie sind nicht nur flammfest, sondern können auch feuchtigkeitsbeständig, UV-beständig und resistent gegen verschiedene Chemikalien sein. Dadurch eignen sie sich für Außenanwendungen oder Umgebungen, in denen sie rauen Bedingungen ausgesetzt sind. So ist beispielsweise die UV-Beständigkeit für Kabel, die in Außenanlagen verwendet werden, von entscheidender Bedeutung, um eine Beeinträchtigung durch Sonnenlicht zu verhindern.

Abschluss

AWM UL2464-Kabel spielen eine wichtige Rolle in modernen elektrischen und elektronischen Systemen. Ihr Design und ihre Konstruktion bieten die Flexibilität, Langlebigkeit und Zuverlässigkeit, die für eine breite Palette von Anwendungen in verschiedenen Branchen erforderlich sind. Da die Technologie immer weiter voranschreitet, wird die Nachfrage nach hochwertigen Verdrahtungslösungen wie AWM UL2464 weiter steigen. Für Ingenieure und Konstrukteure, die diese Kabel in ihren Projekten einsetzen wollen, ist es wichtig, ihre Eigenschaften und Anwendungen zu verstehen. Ob für die industrielle Automatisierung, die Telekommunikation oder die Unterhaltungselektronik - AWM UL2464 ist eine zuverlässige Wahl, die den Anforderungen der heutigen technologischen Landschaft gerecht wird.