Polyurethane (PUR) cables have garnered attention for their flexibility, durability, and overall performance across various industries. When it comes to outdoor environments, where cables are exposed to harsh conditions, the suitability of PUR-Kabel becomes a crucial consideration. This article will delve into the technical aspects of it, examining their material properties, benefits, and limitations, to determine whether they are ideal for outdoor use.

Understanding PUR Cables

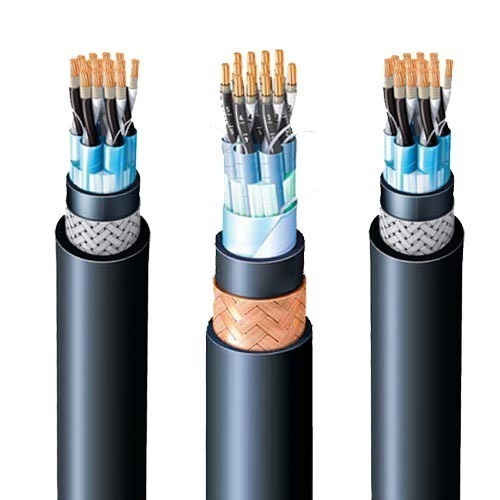

PUR cables are primarily composed of a polyurethane jacket. Polyurethane is a versatile polymer known for its impressive mechanical strength, chemical resistance, and flexibility. These characteristics make it stand out in applications requiring high levels of resilience. The cable’s inner components (conductors and insulation) may vary depending on the intended application, but the jacket material remains consistent, offering protection against environmental factors.

Key Features of PUR Cables

Before diving into their outdoor suitability, it’s essential to highlight some of the key properties of PUR cables:

- Mechanical Strength and Flexibility

They are well-regarded for their mechanical robustness. They resist abrasion, cuts, and punctures, making them ideal for environments where physical damage is a concern. Additionally, PUR’s flexibility allows these cables to be used in dynamic applications involving constant movement, such as in robotic systems and drag chains. - Chemical and Oil Resistance

One of the standout features of PUR is its resistance to chemicals, oils, and other industrial fluids. In applications where exposure to such substances is common, they maintain their integrity without degrading over time. - UV and Weather Resistance

Unlike some other polymers, PUR can offer significant resistance to ultraviolet (UV) radiation and weather conditions, which are crucial for outdoor applications. UV radiation can cause significant degradation in many cable jackets, leading to cracking, brittleness, and eventual failure. PUR’s resistance to these factors enhances its durability outdoors. - Low Temperature Performance

They remain flexible even at low temperatures, making them suitable for environments with varying climates. While some materials become brittle in cold conditions, PUR retains its mechanical properties, ensuring reliable performance.

Outdoor Application Challenges

Outdoor environments present a set of unique challenges that any cable must withstand. These challenges include:

- UV Exposure

Continuous exposure to sunlight can cause degradation in many cable materials. For outdoor applications, cables need to resist UV rays to maintain their functionality over time. - Temperature Extremes

Outdoor environments can range from scorching heat to freezing cold, depending on geographical location and seasonal variations. Cables must be able to handle these temperature extremes without losing flexibility or becoming damaged. - Moisture and Water Exposure

Rain, snow, humidity, and even submersion in water can be expected in outdoor environments. Waterproofing and resistance to moisture ingress are critical for maintaining cable performance. - Mechanical Stress

In outdoor settings, cables can be subjected to physical stress, including stretching, bending, and impacts. Cables need to maintain their mechanical properties under such conditions.

Evaluating PUR Cables for Outdoor Use

Given the challenges listed above, the suitability of PUR cables for outdoor use depends on how well they meet these criteria.

- UV Resistance

They offer substantial resistance to UV rays. This property makes them highly suitable for applications where prolonged exposure to sunlight is inevitable. While other polymer jackets, such as PVC, can deteriorate under UV radiation, PUR maintains its structural integrity and flexibility. This resistance is critical for applications like solar installations, outdoor lighting systems, and equipment placed in exposed environments. - Weather and Temperature Extremes

One of the significant advantages of it is its ability to withstand both high and low temperatures. They remain flexible in cold weather and do not soften excessively in heat. PUR’s resistance to environmental stress cracking ensures that the cables can endure outdoor conditions for extended periods without failure. For applications in regions with harsh winters or scorching summers, they provide a reliable solution. - Water and Moisture Resistance

While they are not inherently waterproof, they do offer excellent resistance to water ingress and moisture. When properly manufactured and installed, they can resist the effects of rain, snow, and even submersion. However, it is important to note that the cable’s overall waterproofing capability also depends on the design of the cable’s connectors and seals. For underwater applications or in areas prone to heavy rainfall, PUR cables with additional waterproofing measures can be highly effective. - Abrasion and Mechanical Stress

The mechanical strength of PUR is one of its defining features. Outdoor environments often involve rough handling, exposure to sharp objects, and potential impacts. They resist abrasion, making them suitable for areas where the cable might be dragged, stepped on, or otherwise physically stressed. Additionally, their flexibility allows them to be used in moving parts, like gates, barriers, and automated systems, without risk of internal damage. - Chemical and Oil Exposure

Outdoor environments, particularly in industrial or urban settings, can expose cables to various chemicals and oils. PUR’s resistance to these substances ensures that the cables do not degrade when exposed to pollutants, chemicals, or oil spills. This property is especially important in outdoor applications like automotive systems, construction sites, and industrial equipment.

Limitations of PUR Cables for Outdoor Use

While PUR cables offer numerous advantages, they also have limitations that need consideration:

- Cost Considerations

They tend to be more expensive than other options, such as PVC cables. For large-scale outdoor installations, this cost difference can become significant. However, the longer lifespan and reduced maintenance requirements of they can offset the initial investment. - Installation and Handling

Although they are flexible, their toughness can make them slightly harder to handle and install compared to other cables. Special tools or techniques might be required, especially in complex installations where the cables need to be routed through tight spaces or around sharp corners. - Compatibility with Connectors

The use of it in outdoor applications requires compatible connectors that maintain the cable’s waterproof and weather-resistant properties. Choosing the right connectors and ensuring proper sealing is essential to avoid water ingress or other issues that could compromise the system’s reliability.

Ideal Applications of PUR Cables Outdoors

Given their properties, PUR cables are particularly well-suited for specific outdoor applications:

- Solar Energy Systems

Solar panels are often exposed to the elements year-round. They provide the UV resistance and weather durability required for reliable operation in solar installations. - Construction and Heavy Equipment

On construction sites, cables are subjected to harsh environments with constant movement, heavy loads, and exposure to dust, mud, and chemicals. They are durable enough to handle these conditions. - Outdoor Lighting and Signage

In outdoor lighting systems, where cables are exposed to sunlight, rain, and temperature changes, they provide long-term performance and reliability. - Industrial Automation in Outdoor Settings

In outdoor factories or automated systems exposed to the elements, they ensures smooth operations without the risk of mechanical or environmental failure. - Agricultural Equipment

Agricultural environments often involve exposure to dirt, moisture, and chemicals, along with significant mechanical stress. They can withstand these conditions, making them ideal for outdoor agricultural machinery.

Conclusion: Are PUR Cables Suitable for Outdoor Use?

PUR cables are undoubtedly suitable for outdoor use, provided they are correctly chosen for the specific application. Their UV resistance, mechanical strength, chemical resilience, and ability to withstand temperature extremes make them an excellent option for challenging outdoor environments. While they come at a higher cost and require careful handling during installation, their benefits in terms of durability and performance often outweigh these factors.

When selecting PUR cables for outdoor applications, it’s essential to consider the specific environmental conditions, installation requirements, and compatibility with other components in the system. By doing so, you can ensure that the cables deliver optimal performance, reduce maintenance needs, and offer a long service life in even the harshest outdoor settings.