Choosing the right aluminium cable is crucial for ensuring efficient and safe electrical systems. They have gained popularity due to their cost-effectiveness, lightweight nature, and excellent conductivity. However, selecting the appropriate aluminium cable involves considering several factors to meet the specific requirements of your application. This comprehensive guide will delve into the critical aspects you need to evaluate when choosing it.

Understanding Aluminium Cables

فوائد

- Cost-Effectiveness: They are generally cheaper than their copper counterparts. The cost savings can be substantial, especially in large-scale projects.

- Lightweight: Aluminium is significantly lighter than copper, making it easier to handle and install. This is particularly advantageous in applications where weight is a critical factor.

- Corrosion Resistance: Aluminium naturally forms a protective oxide layer, enhancing its resistance to corrosion and making it suitable for various environments.

- Good Conductivity: While aluminium has lower conductivity than copper, it is still highly efficient for electrical transmission and distribution.

التطبيقات

They are used in various applications, including:

- Power Transmission and Distribution: Due to their lightweight and cost-effectiveness, they are widely used in power lines and electrical grids.

- Residential and Commercial Wiring: They are also used in building wiring, though careful consideration is needed to ensure safety and compliance with electrical codes.

- Automotive and Aerospace Industries: The lightweight nature of aluminium makes it ideal for use in vehicles and aircraft.

Key Factors to Consider When Choosing Aluminium Cables

1. Electrical Requirements

Understanding the electrical requirements of your application is paramount. This includes the voltage, current-carrying capacity, and the type of load the cable will serve. They come in various sizes and configurations to accommodate different electrical demands.

- Voltage Rating: Ensure the cable can handle the voltage of your application. They are available in low, medium, and high voltage ratings.

- Current-Carrying Capacity: The cable should be capable of carrying the required current without overheating. This depends on the cross-sectional area of the conductor.

- Type of Load: Consider whether the load is resistive (e.g., heating elements) or inductive (e.g., motors), as this affects the choice of cable.

2. Environmental Conditions

The environment in which the aluminium cable will be installed plays a significant role in the selection process. Factors to consider include:

- Temperature: Extreme temperatures can affect the performance and lifespan of the cable. Ensure the cable can withstand the temperature range of the installation environment.

- Moisture and Corrosion: In areas prone to moisture or corrosive elements, choose it with appropriate insulation and protective coatings.

- UV Exposure: For outdoor applications, select cables with UV-resistant insulation to prevent degradation from sunlight exposure.

3. Mechanical Properties

The mechanical properties of them are essential for ensuring durability and reliability. Key considerations include:

- Flexibility: Depending on the installation, you may need flexible aluminium cables that can bend and maneuver through tight spaces.

- Tensile Strength: The cable should have adequate tensile strength to withstand mechanical stresses during installation and operation.

- Abrasion Resistance: In environments where the cable may be subject to physical wear and tear, choose cables with high abrasion resistance.

4. Standards and Certifications

Ensure the aluminium cables you choose comply with relevant standards and certifications. This guarantees the cables meet industry requirements for safety and performance. Look for cables certified by recognized organizations such as:

- International Electrotechnical Commission (IEC)

- Underwriters Laboratories (UL)

- National Electrical Code (NEC)

- British Standards (BS)

5. Compatibility with Connectors and Terminations

Proper termination and connection are vital for maintaining electrical integrity and preventing issues such as overheating and arcing. Consider the following:

- Compatible Connectors: Ensure the connectors are designed for it, as using incompatible connectors can lead to galvanic corrosion.

- Proper Crimping and Sealing: Use appropriate tools and techniques for crimping and sealing to ensure secure and reliable connections.

6. Cost and Availability

While they are generally more cost-effective than copper cables, it is essential to balance cost with performance and reliability. Consider the total cost of ownership, including installation, maintenance, and potential downtime.

Types

- Solid Aluminium Cables

They consist of a single, solid conductor. They are commonly used in residential wiring and small-scale applications. These cables offer simplicity and ease of installation but are less flexible than stranded cables.

- Stranded Aluminium Cables

They are made up of multiple strands of aluminium wire twisted together. They provide greater flexibility and are suitable for applications requiring frequent bending and movement, such as in automotive and industrial settings.

- Aluminium Alloy Cables

Aluminium alloy cables incorporate other elements, such as magnesium and silicon, to enhance their mechanical properties. These cables offer improved strength, flexibility, and resistance to creep, making them suitable for demanding applications.

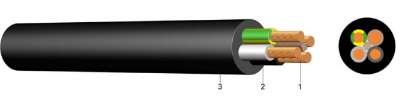

- Armoured Aluminium Cables

They have an additional layer of protection, usually made of steel or aluminium, to shield the cable from mechanical damage. They are ideal for underground installations and harsh environments.

- Aerial Bundled Aluminium Cables

Aerial bundled cables (ABC) consist of several aluminium conductors bundled together and insulated. They are commonly used in overhead power distribution, offering advantages such as reduced power loss and increased safety.

Installation Best Practices

Proper Handling and Storage

Proper handling and storage of aluminium cables are crucial to prevent damage and ensure optimal performance. Follow these guidelines:

- Avoid Excessive Bending: They should not be bent excessively to prevent damage to the conductor and insulation.

- Protect from Moisture: Store cables in a dry environment to prevent moisture ingress, which can lead to corrosion.

- Prevent Physical Damage: Avoid dragging cables across rough surfaces and protect them from impact during transportation and installation.

Correct Sizing and Ampacity

Selecting the correct size and ampacity of it is essential to prevent overheating and ensure efficient electrical transmission. Use appropriate tables and calculations to determine the correct cable size based on the current carrying capacity and installation conditions.

Secure Connections

Ensuring secure connections is vital for maintaining the integrity of it. Follow these practices:

- Use Compatible Connectors: Always use connectors designed for aluminium cables to prevent galvanic corrosion and ensure reliable connections.

- Proper Crimping: Use the correct crimping tools and techniques to achieve secure and durable connections.

- Regular Inspection: Periodically inspect connections for signs of wear, corrosion, or loosening and perform maintenance as needed.

Compliance with Electrical Codes

Ensure your installation complies with relevant electrical codes and regulations. This includes following guidelines for cable routing, securing, and protection to ensure safety and reliability.

Common Challenges and Solutions

Oxidation

Aluminium cables are prone to oxidation, which can affect their conductivity and connection integrity. To mitigate this:

- Use Anti-Oxidant Compounds: Apply anti-oxidant compounds to connections to prevent oxidation.

- Ensure Proper Sealing: Use appropriate sealing techniques to protect connections from moisture and air exposure.

Thermal Expansion

Aluminium expands and contracts with temperature changes, which can affect connections. To address this:

- Use Proper Terminals: Select terminals designed to accommodate thermal expansion and contraction.

- Regular Maintenance: Periodically check and tighten connections to ensure they remain secure.

Mechanical Stress

They can be susceptible to mechanical stress during installation and operation. To minimize this:

- Use Flexible Cables: Choose stranded or flexible aluminium cables for applications requiring frequent movement or bending.

- Provide Adequate Support: Use proper cable supports and routing to minimize mechanical stress on the cables.

خاتمة

Choosing the right aluminium cable involves a comprehensive evaluation of various factors, including electrical requirements, environmental conditions, mechanical properties, and compliance with standards. By understanding the different types of its and following best practices for installation and maintenance, you can ensure reliable and efficient electrical systems. They offer numerous benefits, including cost-effectiveness, lightweight, and good conductivity, making them an excellent choice for a wide range of applications.

When selecting it, consider the specific needs of your project and consult with professionals if necessary. Properly chosen and installed they will provide safe and efficient electrical transmission, contributing to the overall success and longevity of your electrical systems.